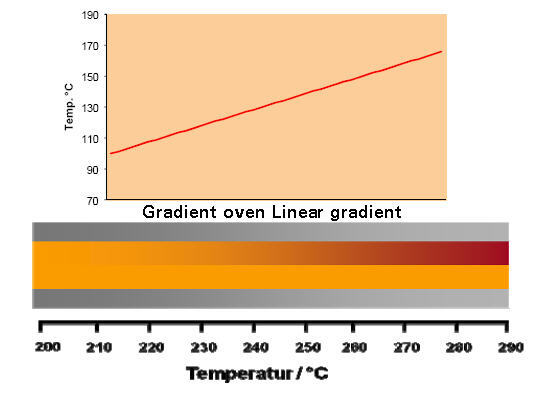

Gradient Oven

Coatings & Industry > Physical properties > Drying Time

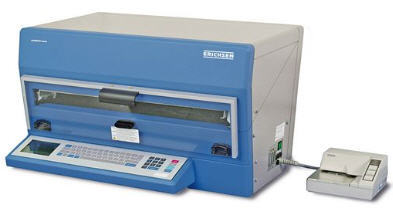

Gradient-oven, Model 432/I

- Efficient measurement of temperature-dependent properties

- Simulation of industrial stoving processes with programmable gradients

For evalution the baking and drying behavior of liquid coatings, powder coatings, resins, plastics, etc., with an operating temperature of 30 °C to 250 °C, operation and controlling via built-in alphanumeric keypad (menu-guided English, French or German), three interfaces (controlling a printer, output date to a PC, connecting an oven temperature recorder/data logger), built-in software for connecting a data logger, safety protective shutter.

Purpose and Application

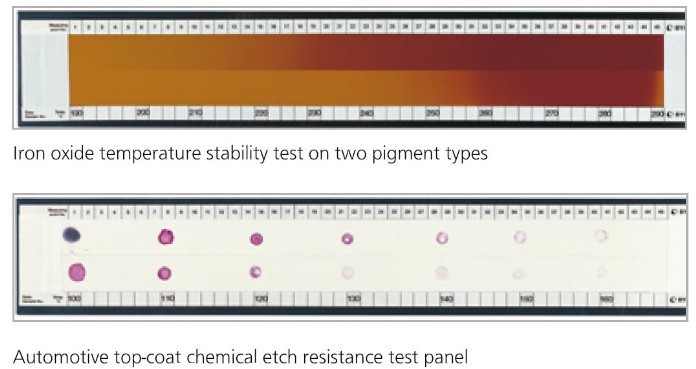

Acid rain, bird droppings, fuel, antifreeze and many other environmental factors can damage automotive finishes. Especially in summertime, some substances can be very aggressive and cause severe damage. Therefore, automotive paint manufacturers as well as auto makers need to find out how different environmental phenomena will interact with a coating system.

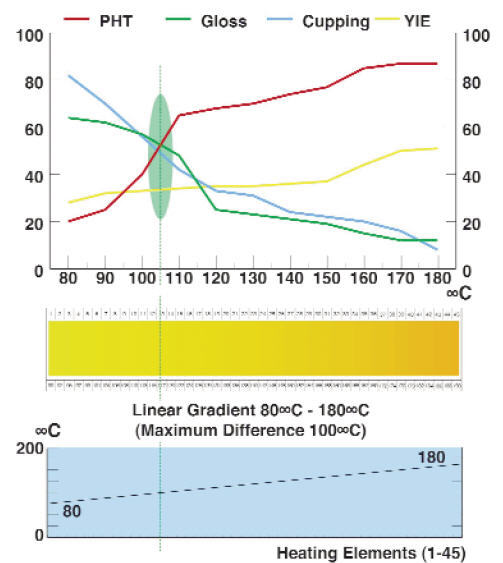

For the development of stove enamel systems as well as for their quality testing it is of great importance to assess the temperature range and the max. temperature limit, respectively, where the components of the lacquer formulations (and thus also potentially the properties and the quality of the whole thing) begin to change.

The well-known main example for this are the yellowing of binding agents as well as the change in colour of pigments.

Concerning the subject of baked coatings within industrial production conditions, the accurate control of the corresponding processes is of crucial importance to achieve and continuously maintain/ guarantee the specified qualitative characteristics of the coating.

Due to different reasons, the actually existing conditions do not always correspond exactly to the preset process run which in the “worst case“ may cause severely high non-conformity costs.

The Gradient-oven 432 offers the possibility of a needs-based optimizing of the process for the product in question.

The „actual condition“ in the stove enameling production line, beforehand determined by means of an oven temperature recorder, can be simulated at the best via a requirement-orientated setting of an appropriate gradient and thus allows a nearly perfect 1:1 simulation of the respective stoving condition, however on the desired laboratory scale saving time and expenses.

Technical Data

Voltage : 230 V, 50/60 Hz

Power Consumption : 3400 VA

Heating Surface : 520 x 100 mm

Test Surface : 500 x 70 mm

Heating Elements : 45 pcs.

Pressure Platform : reciprocates automatically (16 kp) for insertion and removal of panel

Linear Gradient : max. temp. difference between 30 and 250 (320) °C: 100 °C;

Step Gradient : with 2, 3 or 4 steps: max. temp. difference between two steps: 50 °C

Heat-Up-Speed : 2 °C to 30 °C/min, programmable

Baking Time : in sec. and min.

Memory max. : 10 gradients

Accuracy control accuracy of the heating elements: < ± 2 °C surface temperatures on 0.8 mm test panels from element 3 up to 43:

to 200 ° ± 2 °Cto 250 ° ± 3 °Cto 320 ° ± 5 °C

measured under specified test conditions

Dimensions : 465 x 720 x 595 mm

Weight : 50 kg

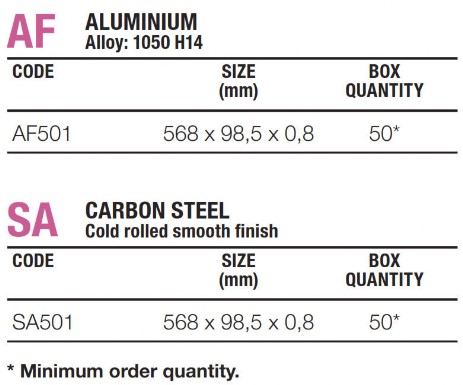

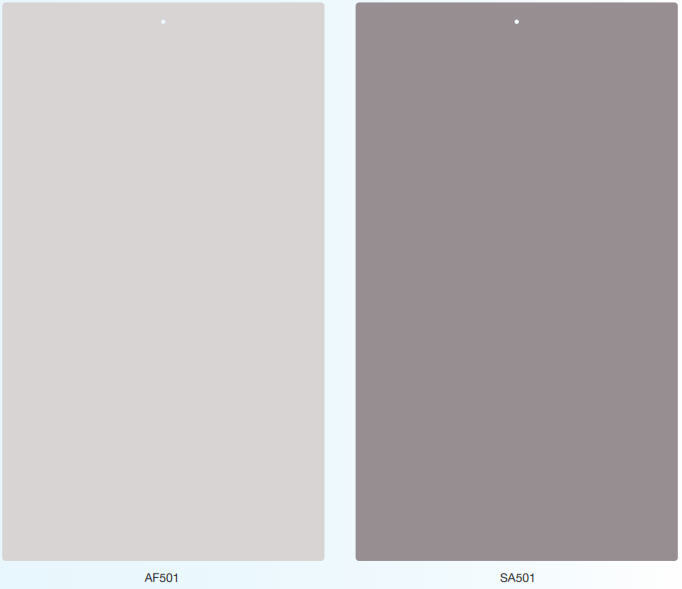

PANELS FOR GRADIENT OVEN

Carbon steel and aluminium panels for Gradient Ovens.