Brinell

Metal Testing > Hardness Testers > Benchtop

ATI B3000

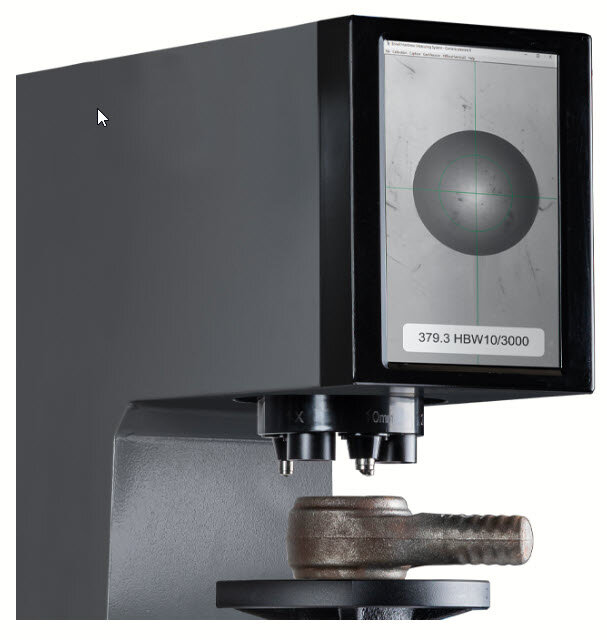

ATI B3000 is an automatic Brinell hardness tester, fully performant and easy to use, making it the best choice for efficience and to mesure any surface on large or small products.

Automatic Brinell test cycle directly in production line and in laboratory

ATI B3000 is automatic Brinell hardness tester for Brinell hardness testing.

Simply select the desired hardness scale and press the START button.

The tester automatically positions the test piece against the indenter, initiating the loading cycle with no manual effort required.

The integrated turret efficiently manages indenter and objective switching, ensuring seamless operation.

By touching the indentation image, you can instantly view the results on the large graphic display.

Once the measurement is complete, the ATI B3000 is ready for the next test, enhancing your productivity.

With its combination of performance and user-friendliness, the ATI B3000 hardness tester is the ideal solution for accurately measuring hardness on various surfaces, whether for large or small products.

Choose the ATI B3000 for reliable and efficient Brinell hardness testing.

Model: ATI B3000

Brinell hardness scales: HBW 2.5/62.5 , HBW 2.5/187.5 , HBW 5/62.5 , HBW 5/250 ,

HBW 5/750 , HBW 10/100 , HBW 10/500 , HBW 10/1500 , HBW 10/3000

Test force (kgf): 62.5 Kgf (612.9N), 100 Kgf (980.7N), 125 Kgf (1226N), 187.5 Kgf (1839N),

250 Kgf (2452N), 500 Kgf (4903N), 750 Kgf (4905n), 1000 Kgf (7905n),

1500 Kgf (14710N), 3000 Kgf (29420N)

Loading system: Electronic control of load cells in “Closed-Loop”

Auto turret standard: 2 steps (1indenter / 1 optical len 20X)

Auto turret as option: 5 steps (3 indenters / 2optic lens 20X 40X)

Auto turret rotation: Horizontally 360° (2 steps or 5 steps)

Compliance standards: ISO 6506, ASTM E10 and equivalents

Accuracy: Accuracy better than 1% (62.5 – 3000 Kgf);

Accuracy better than 0.5% (500 – 3000 Kgf)

Measuring device resolution: 0.1 μm

Dwell time: 0-99 seconds

Height capacity: 310 mm

Depth capacity: 250 mm

Measuring range: 15.9-650 HBW (ASTM E10 (Recommended effective hardness value)

Camera resolution: 1,2 MPixel

Measurement methods: Manual and automatic

Data store: The measured values are stored in EXCEL format on a USB flash disk

Power supply: 220 V – 50/60 Hz single phase

Total dimensions: 120 x 120 x 160 cm– Weight: 160/200 kg

ATI B3000-2

ATI B3000-2ATI B3000-2 is a Brinell hardness tester that is fully compliant with ASTM E10-23 and ISO 6506 standards, making it an ideal solution for accurate and reliable hardness testing.

Add ATI BR

ATI BR is a digital and portable microscope for Brinell and Vickers indentation reading.

The system complies with ISO 6506, ISO 6507, ASTM E10, and ASTM E92 standards. Brinell and Vickers hardness tests can be performed directly on the production line, eliminating the need to move the components. Suitable for parts of any shape or size.

Software

The software is designed to guide the user through the Brinell hardness testing process. First, all relevant test parameters must be entered, including load, dwell time, and indenter specifications.

Once these parameters are set, the user clicks the ‘CALCULATE’ button, and the software automatically processes the data to provide the final hardness test result.

Set the hardness test scales, set the standard test method, conversion scales, manage the instrument tools and check if the installed instrument is correct and compliant with the selected hardness test method.

Model: ATI B3000-2

Brinell hardness scales: HBW 2.5/62.5 , HBW 2.5/187.5 , HBW 5/62.5 , HBW 5/250 ,

HBW 5/750 , HBW 10/100 , HBW 10/500 , HBW 10/1500 , HBW 10/3000

Test force (kgf): 62.5 Kgf (612.9N), 100 Kgf (980.7N), 125 Kgf (1226N), 187.5 Kgf (1839N),

250 Kgf (2452N), 500 Kgf (4903N), 750 Kgf (4905n), 1000 Kgf (7905n),

1500 Kgf (14710N), 3000 Kgf (29420N)

Loading system: Electronic control of load cells in “Closed-Loop”

Turret: 1 ball Brinell indenter

Compliance standards: ISO 6506, ASTM E10 and equivalents

Accuracy: Accuracy better than 1% (62.5 – 3000 Kgf);

Accuracy better than 0.5% (500 – 3000 Kgf)

Measuring device resolution: 0.1 μm

Dwell time: 0-99 seconds

Height capacity: 290 mm

Depth capacity: 210 mm

Measuring range: 15.9-650 HBW (ASTM E10 (Recommended effective hardness value)

Measurement methods: Manual

Power supply: 220 V – 50/60 Hz single phase

Total dimensions: 450 x 200 x 700 cm – Weight: 160/200 kg

SERIE LD - BRINELL TESTING SOLUTIONS

Digital hardness testers for Brinell and Vickers test method in compliance with ASTM, ISO and JIS hardness standards.

Load range from 10 to 3000 kgf. LD 3000 hardness testers are low cost bench hardness testers with high accuracy standards.

Really simple to use, just one single button for the entire test. Load forces are applied through load cells and controlled in "Closed Loop" with a frequency of 1 khz, assuring perfect linearity in every range.

Hardness tests on all metals: iron, steel, tempered steel, cast iron, brass, aluminum, copper and metal alloys.

TECHNICAL FEATURES | LD 3000 |

Standards | EN-ISO 6506-1 / EN-ISO 6507 / EN-ISO 6508-2 / ASTM E-10 / ASTM E-18 / ASTM E-384 / ASTM E-92 |

Indenter and clamping-hood stroke | 30 mm |

Elevating screw stroke | 150 mm. Removing the elevating screw, the vertical capacity increase till 300 mm for large samples. |

Depth capacity | 190 mm |

Test loads | Brinell: 98.07 - 147.1 - 294.2 - 306.5 - 612.9 - 1839 - 2452 - 4903 - 7355 - 9807 - 29421 N (10 - 15 - 30 - 31.2 - 62.5 - 187.5 - 250 - 500 - 750 - 1000 - 3000 kgf) Rockwell (On request): 588.4 - 980.7 - 1471 N (60 - 100 - 150 kgf) Vickers (On request): 98.07 - 147.1 -294.2 - 490.3 - 980.7 N (10 - 15 - 30 - 50 - 100 kgf) |

Feasible tests | LD 3000: Only indentation LD 3000 A: Automatic indentation reading with onboard LCD and portable probe Brinell HBW 1/10 - 1/30 - 2.5/62.5 - 2.5/187.5 - 5/25 - 5/62,5 - 5/125 - 5/250 - 5/750 - 10/100 - 10/250 - 10/500 - 10/1000 - 10/1500 - 10/3000 Vickers HV 3 - HV 5 - HV 10 - HV 20 - HV 30 - HV 50 - HV 100 (Only indentation) LD 3000 B: Automatic Brinell HBWT and Rockwell measurements Brinell HBWT 2.5/62.5 - 2.5/187.5 - 5/125 - 5/250 - 5/750 - 10/500 - 10/1000 - 10/1500 - 10/3000 Rockwell HRA - HRB - HRC - HRD - HRF - HRG - HRL - HRM - HRR Vickers HV 3 - HV 5 - HV 10 - HV 20 - HV 30 - HV 50 - HV 100 (Only indentation) |

Accuracy | Better than 0.5 % |

MRS JET 3000

Automatic hardness tester studied to be inserted in production lines for high speed Brinell HBWT hardness measurements in compliance with ASTM, ISO and JIS. MRS JET 3000 has been studied to be used on conveyors and robotized lines with PLC remote control.

The motorized measuring head has a long vertical stroke and moves automatically down to make contact with the sample's surface (AFFRI system).

MRS JET 3000 is supplied with a wide touchscreen for a easy management of the software and testing cycles in production lines.

Load forces are applied through load cells and electronically controlled in Closed Loop (Pat. Affri).

Exact hardness result on the first test, absolute accuracy (better than 0.5 %) in every condition.

Hardness tests on all metals in accordance with Brinell test method: iron, steel, tempered steel, cast iron, brass, aluminum, copper and metal alloys.

Test loads: from 5 to 3000 kgf (From 49,03 to 29421 N))

TECHNICAL FEATURES | MRS-JET 3000 |

Standards | EN-ISO 6506 / ASTM E18 / ASTM E103 |

Vertical head stroke | Programmable distance with automatic contact |

Indenter and clamping-hood stroke | 300 mm (More on request) |

X/Y table | 400 x 400 mm |

Depth capacity | 240 mm |

Force range | Brinell: 49.03 - 61.29 - 98.07 - 153.2 - 245.2 - 294.2 - 306.5 - 612.9 - 1226 - 1839 - 2452 - 4903 - 7355 - 9807 - 29421 N (5 - 6.25 - 10 - 15.6 - 25 - 30 - 31.2 - 62.5 - 125 - 187.5 - 250 - 500 - 750 - 1000 - 3000 kgf) |

Feasible tests | Brinell: HBWT |

Accuracy | Better than 0.5 % |

BK30 BRINELL SCOPE

AFFRI, Brinell, Portable

Portable digital microscope for automatic Brinell measurement indent reading conforms to ASTM E10/ISO 6506 international standards.

Portable Brinell microscope for automatic ball indentation measurement Ø 2.5 or 5 or 10 mm

- User friendly and compact

- Automatic light adjustment

- Accuracy and repeatability of measurement +/- 1%

- It run on Windows®

- Export data and images as jpg, bmp, PDF, Excel, txt, csv

- Create and print reports with results and statistics

- Internet connection for remote data network, calibration, service and software updates

BRINELL HBWT ISO 6506 – ASTM E10

- HBW 2.5/15.62 HBW 2.5/31.25 HBW 2.5/15.6 HBW 2.5/187.5 HBW 5/25 HBW 5/62.5 HBW 5/125 HBW 5/250

- HBW 5/750 HBW 10/100 HBW 10/250 HBW 10/500 HBW 10/1000 HBW 10/1500 HBW 10/3000

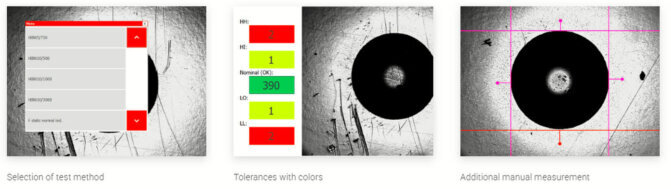

THE SOFTWARE

- The software controls the whole measurement avoiding setting errors or operators mistakes:

- Setup the hardness test scales, the properties of the camera, the test method standards, and the conversion scales.

- Export results as a TXT file or use the USB/WI-FI/Bluetooth outputs to connect the tablet to printers.

- Lists all of the readings done and their associated image. Chart the results and statistics highlighted according to their tolerance values (LOW, OK, HIGH).