508 for VDA

Coatings & Industry > Mechanical properties > Flexibility and toughness > Stone Hammer Blow Tester

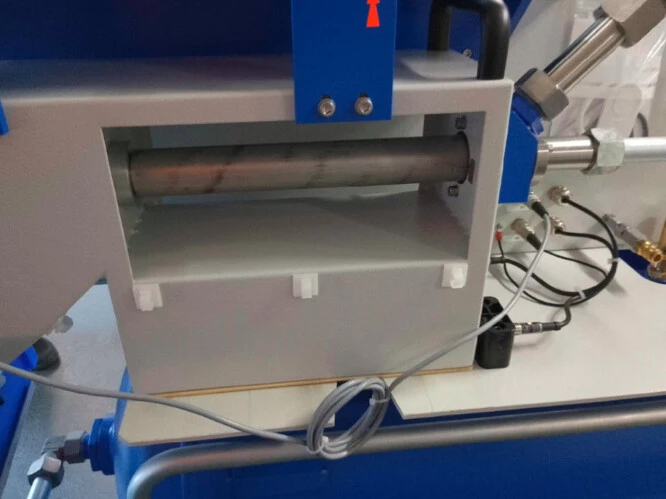

VDA Stone Hammer Blow Test Instrument,

MULTI GRIT TESTER 508 VDA

Purpose and Application

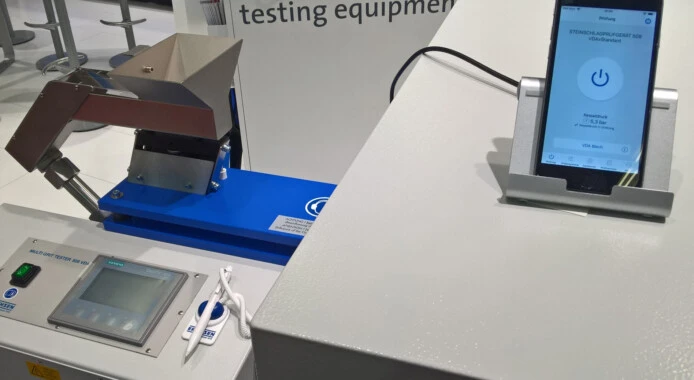

The MULTI GRIT TESTER 508 VDA is a stone hammer blow testing instrument that at first was developed in co-operation with the "Verband der Automobilindustrie (VDA)" (Association of the Automotive Industry) but now also meets the specifications of national and international standards.

The MULTI GRIT TESTER 508 VDA is used to assess the ability of single and multiple layers of paints and similar coating materials to stand up to the impacts caused by small bodies of low mass hitting the specimen at high speed as experienced on road and rail vehicles and other equipment used in the transport field.

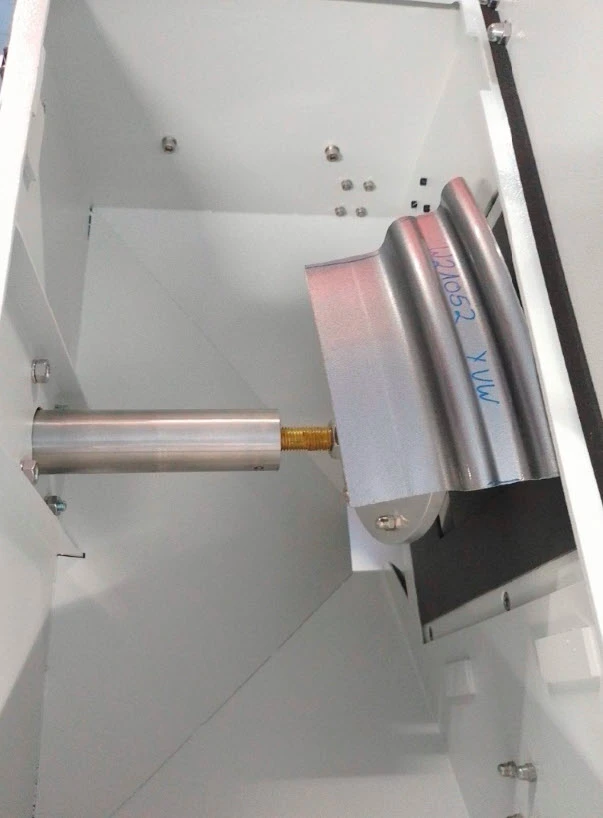

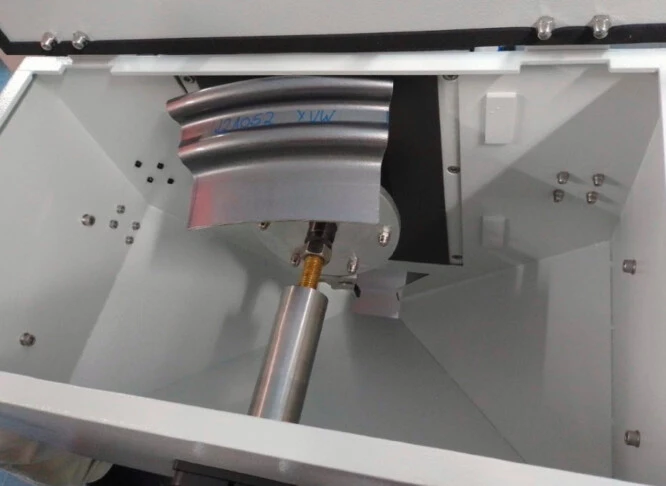

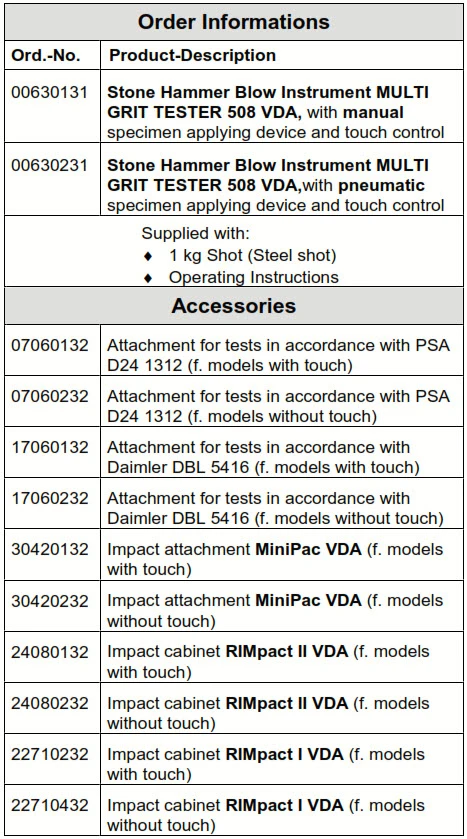

Accessories (option)

Technical Data

Dimensions (W x D x H): 1750 x 500 x 1220 mm

Weight (net): approx. 100 kg

Compressed air connection: min. 6 bar / max. 10 bar, requires connecting hose with ID 13 mm

Filling pressure control: approx. 5 bar, factory set

Working pressure: (0 - 3) bar / quality class I

Time for feeding shot: (5 - 30) s / adjustable

Display: 8 digits, lighted LCD, height of digits 11.5 mm

Power supply: 85-264 VAC / 47-63 Hz(control circuit volt. 24 V)

Shot (Steel shot acc. to VDA): GH Diamant 06302, sharp-edged (3.5 - 5 mm)

Note: By now many users also apply further types of shot material, e. g. in accordance with the specifications of different international vehicle manufacturers or internal specifications based on experience in their own company.

Ex. Steel Shot (2.0 - 2.8 mm) GH-K Diamant (for shot test acc. to Daimler DBL 5416) available on request

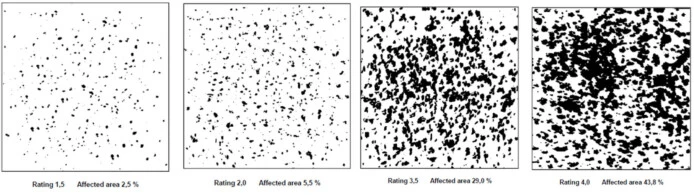

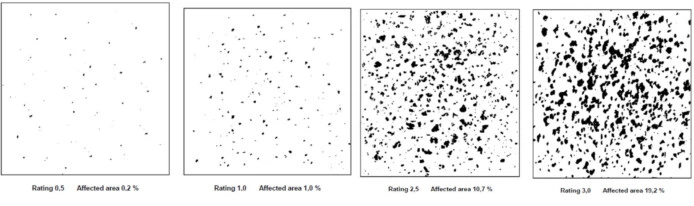

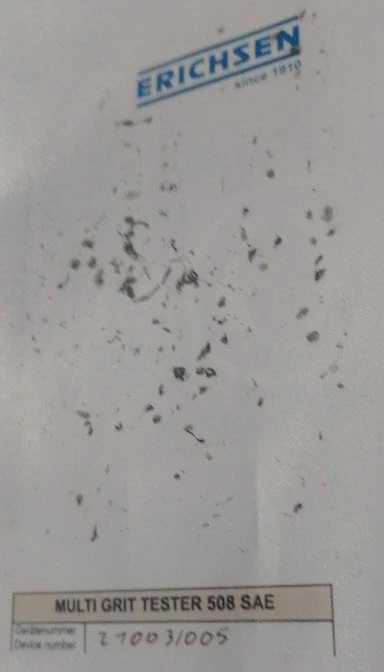

Rating by means of reference images according ISO 20567-1

Most standards including ASTM and ISO describing for evaluation of results a visual comparison of samples with reference images and/or manual counting of impacts

Available on request :

- 10 calibration sandwiches 100 mm x 200 mm (each 1 x white cardboard with already pre-printed legend form,

- carbon paper and clear PVC foil ~150 μm)

- and 1 plate of stainless steel (100 mm x 200 mm x 1 mm)

Please note, that the execution of the Calibration Sandwich differ a little bit from the recommendations of the EN ISO 20567-1:2006 (E) standard:

- we use some white cardboard instead of the recommended white paper

- we use some PVC foil (~150 μm) instead of the recommended PE foil (150 - 200 μm)

But, however, as you know we are since a lot of years the manufacturer of this kind of testing machine and the current specification of the Calibration Sandwich is a result of our long lasting experience in this field.