Impact acc. to Wegner

Coatings & Industry > Mechanical properties > Flexibility and toughness

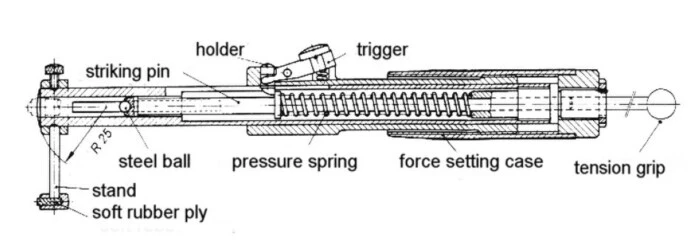

Impact Tester acc. to Wegner, Model 305

Purpose and Application

The Impact Testing Device - Wegner type,

Model 305, is an indispensable aid for testing enamelling in accordance with DIN 51 155.

This practical and handy testing device, which can easily fit into every briefcase, avoids troublesome dismantling and transport.

It can be used outside the laboratory or the workshop for testing purposes.

Objects can therefore be tested on location and in the position in which they happen to be and where they are in use.

This is the only way to test certain parts of enamel surfaces at all, as they are otherwise inaccessible with large and cumbersome testing apparatus.

Standards

- DIN EN 438-2

- DIN ISO 4532

- ISO 4532

- ISO 4586-2

305 Impact tester according to ISO 4532/4586,

5 mm diameter ball, up to 90 N

305 Impact tester according to ISO 4532/4586,

5 mm diameter ball, up to 90 N,

with support device* according to DIN 53 799

Impact Tester acc. to Wegner, Model 305 - including support

The Model 305 is also suitable for impact tests on plastic surfaces using a special support for this testing purpose (the support cannot be ordered separately).

DIN 51 155, including support* according to DIN 53 799