Impact

Coatings & Industry > Mechanical properties > Flexibility and toughness

Various standardized versions

Each version can be upgraded with various test sets

ASTM D 2794

ISO 6272-1

ISO 6272-2

Principle of Variable Height Impact Test

Surface coatings are frequently subjected to impact and shock loads which deform the base material, thus placing stress on the adhesion and cohesion of the coating.

ERICHSEN Impact Tester 304 are used for determination of impact resistance, deformability and tensibility of coatings and substrates as well as adhesion of the coatings.

The ball impact test simulates this type of stress under standardised conditions.

A ball punch of defined weight the bottom of which is of fixed diameter, is dropped freely down a guide tube from an agreed or variable height.

In this case a defined weight, which sample-side end is formed as hemispherical head (ASTM and ISO-1) or as male die tappet with fixed diameter, is dropped freely down a guide tube from an agreed or variable height.

After the impact, the deformed zone of the specimen surface is examined for cracks and flaking.

The ball impact test is comparable to a dynamic version of the ERICHSEN Cupping Test.

The following standard versions are available:

Impact Tester, Model 304 ASTM

(for test according to ASTM D 2794) consisting of:

- Basic plate and side plate with set-up and guide tube

- ASTM falling weight incl. ASTM hemispherical head (Ø 15,9 mm) – 1 kg

- ASTM die (inside Ø 16,3 mm)

| In the following table these instrument parameters are summarised and the standard versions of the ERICHSEN Impact Tester, Model 304, are shown in relation to the different impact test standards. | |||||

| Standard | Ball Dia. | Die I.D | Falling Weight | Scale/Division | ERICHSEN Model |

| ASTM D 2794 | 0.63“(15,9 mm) | 0.64“(16.3 mm) | 1 kg | 80/2 inch pounds | 304 ASTM |

ISO 6272-1 (direct impact) | 0.79" (20 mm) | 1,1“ (27 mm) | 1+1 kg ** | 1000/5 mm | 304 ISO-1 |

ISO 6272-2 (indirect impact) | 0,5“ (12,7 mm) & 0.63"(15,9 mm) | 0.64“(16.3 mm) | 1+1 kg ** | 1000/5 mm | 304 ISO-2 |

| ** The basic weight is doubled by bolting on a supplementary weight (up to 4 kg possible) | |||||

Model 304 – General Description

The Impact Tester, Model 304, in all its variations, consists of a sturdy base plate with attached holding arm into which the slotted fall tube is clamped (transverse thread screw).

In the ISO versions the screw is tightened with a clamping lever enabling the apparatus to be set quickly for different specimen

thicknesses.

The lever can also be pulled out a short way against a spring force.

It is thus disengaged and can be turned freely.

Below the falling tube and carried in the base plate is mounted the die in accordance with the relevant standard.

The die is easily exchangeable but at the same time is accurately fitted so that the centre lines of guide tube and die coincide.

Located at the bottom end of the falling weight is the ball punch or male die tappet appropriate to the die being used on its side, it has a protruding pin which is guided in the slot along the length of the tube, used to lift the weight to the desired height manually.

On the ISO versions the mass of the falling weight can be doubled by bolting on an additional weight (a total weight up to 4 kg is possible).

Scales are mounted along the slot which in the case of instruments for ISO standards are considered in „cm“, or for ASTM instruments in „inch lbs“.

Procedure for the Impact Test

After preparing the specimen as laid down in the standards (in respect of surface treatment of base material, application of coating, hardening procedure, storage, coating thickness measurement, possible cross cut test etc.) two fundamental decisions have to be taken:

- The ball impact is directed onto the coating for a concave deformation (intrusion) or on the other side for a convex deformation (extrusion). The standards listed give the user the choice between these two, to select or make an agreement for one or the other method

- In respect of the energy for the deformation the first possibility is to employ an agreed value for the potential energy at the beginning of the fall. The impact test in this case gives the go/no-go test or pass/fail answer in respect of the resistance of the coating from the point of view of the formation of cracks under rapid deformation. This method gives only a qualitative result but enables a batch of specimens to be tested in rapid succession.

A quantitative result is obtained, if repeated impact tests are performed to establish the minimum energy to damage the material. In this case, the distance of drop and hence the energy of impact is varied until the formation of cracks and/or loss of adhesion is observed. The value of energy which resulted in such damage has to be confirmed by repeated tests using also further specimen panels. If different results are obtained, it is recommended to establish a mean value.

A fundamental point - and this applies also to the go/no-go test - is to ensure that the test is conducted at an adequate distance from the edge (at least 35 mm) and also from the previous tests on the specimen (minimum 70 mm centre to centre).

Accessories

There is the option, to retrofit an existing standard Impact Tester 304 with retrofit kits that standardized tests according to ASTM, ISO-1 and ISO-2 can be performed.

Also available:

ISO Screw-on weight (1 kg) Hold-/Release Device for falling weight )

Safety Fixing Device "Prisma", wedge-shaped device for fixing round specimens (e.g. pipes), incl. 2 fixing belts

Samples to be used with impact

and conical mandrel tester.

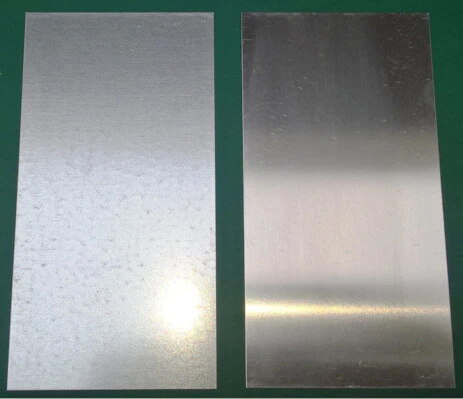

ALU

Ref 284-ALU :

Alu 5754 (AIMg3) sample, 190 x 100 x 0,5 mm

STEEL

Ref 284-STEEL :

Cold rolled steel sample type DC04, 190x100x0,5 mm

GALVANISED STEEL

Ref 284-GALVASTEEL :

Zinc fire steel specimen type DX51D+Z275, 190x100x0,5mm