Corrocutter

Coatings & Industry > CORROSION > Specimen preparation

Test Panel Scratcher CORROCUTTER 639

Purpose and application

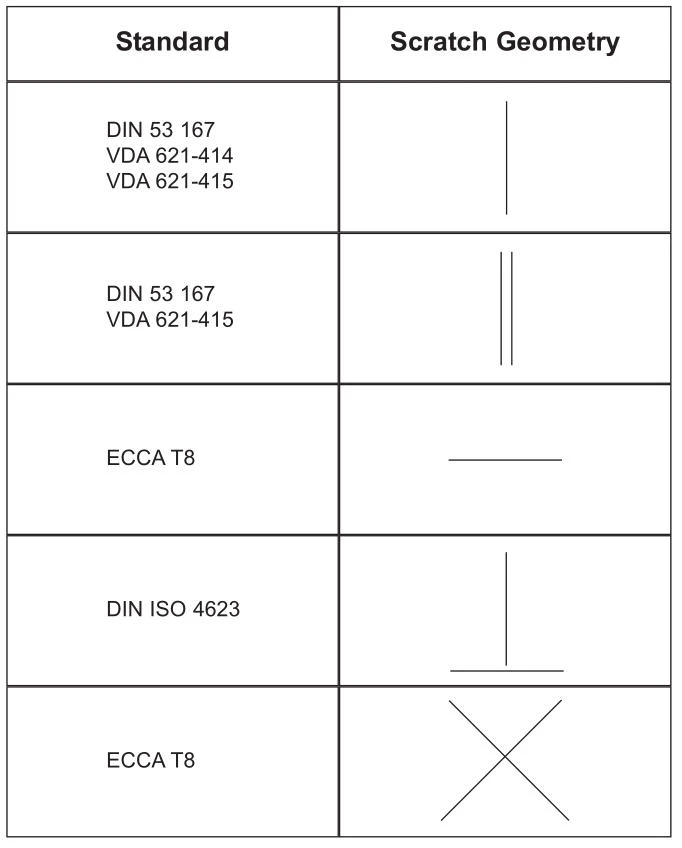

The Test Panel Scratcher CORROCUTTER 639 is designed for the application of defined and reproducible scratches through coatings on test panels intended for subsequent corrosion tests. For this purpose the frequently used scratching tools in accordance with van Laar, with Clemen as well as with Sikkens are available.

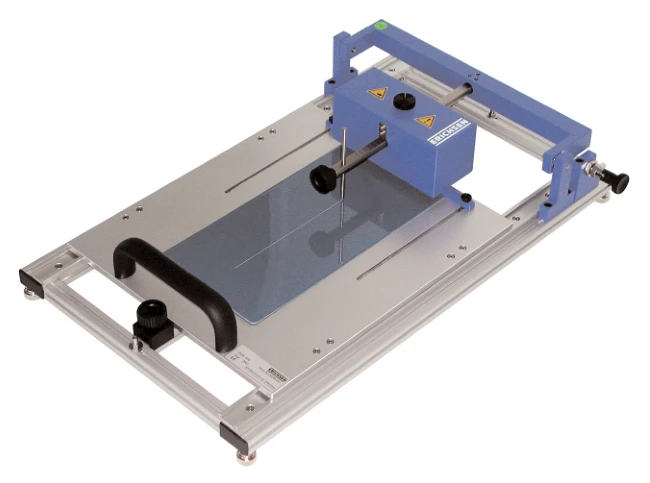

The CORROCUTTER 639 prevents from the strain put to fingers and wrists of users when scratching by hand large series of test panels using a scratching stylus.

Design

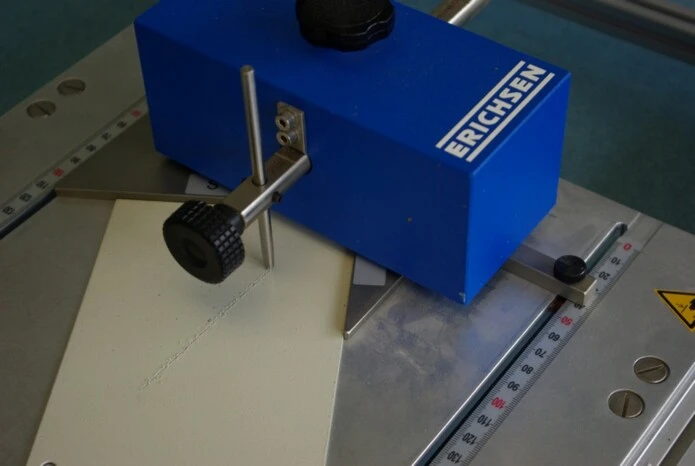

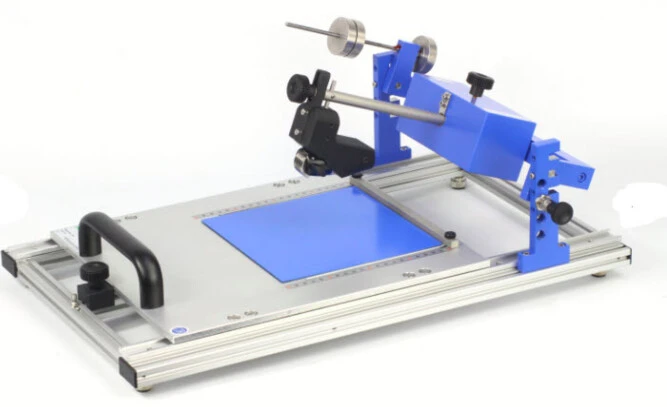

The CORROCUTTER 639 is a desk-top unit. The slide is equipped with a linear guide (sliding bearing) and is moved by hand.

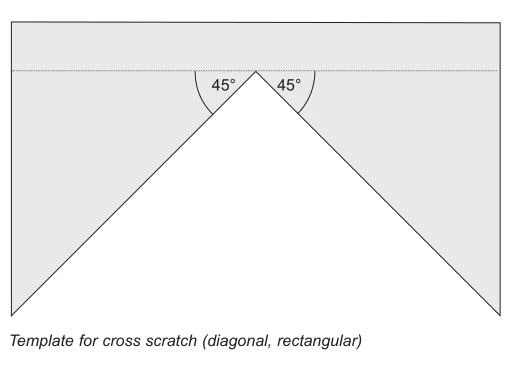

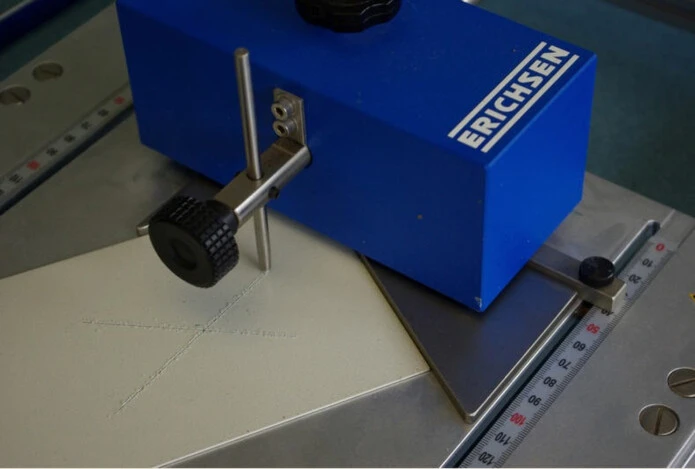

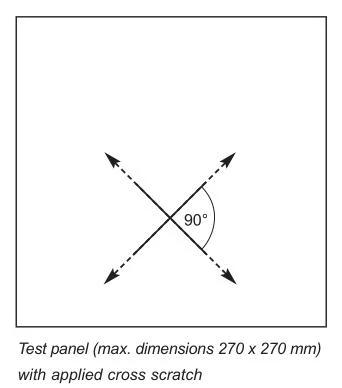

When using the cross scratch template it is possible to apply also scratches in the shape of a diagonal, rectangular cross with variable scratch lengths. For this purpose the cross scratch template is positioned against the adjustable ledger of the CORROCUTTER 639. The test panel to be scratched is placed into the jog of the cross scratch template and scratched by executing the usual procedure.

Then the scratching procedure is repeated on the test panel having been rotated through 90° and thus the required cross scratch is completed. The maximum dimensions of the test panel are 270 x 270 mm.

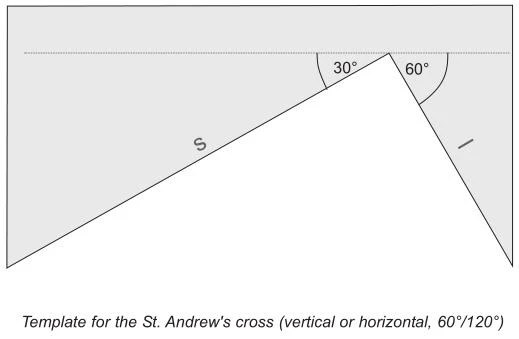

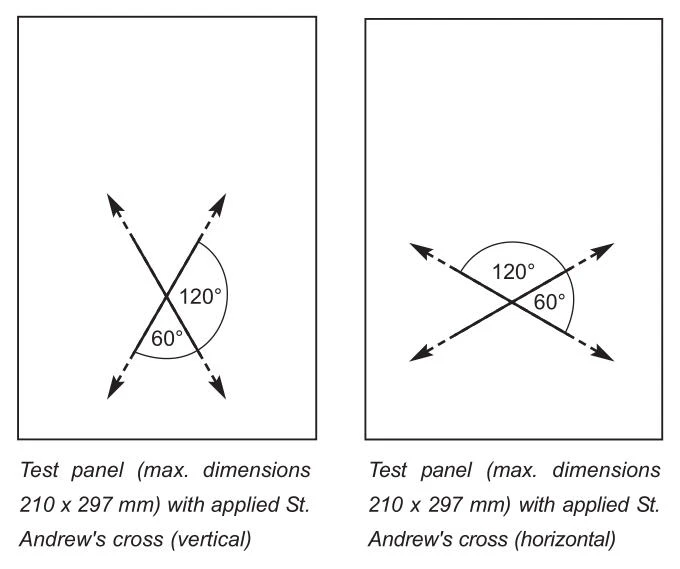

The St. Andrews's cross template enables the application of scratches producing a St. Andrew's cross either in a horizontal or in a vertical position. For this purpose the template has to be turned round (upside down) after the first scratch. Then the test panel has to be positioned after having been rotated through 90° and the second scratch is carried out.

Decisive for the vertical or horizontal position of the St. Andrew's cross that will be produced, is the marked edge of the ledger of the template jog against which the lower edge of the test panel is positioned for the first scratch. The two edges of the ledger are marked - one by "s" for upright position and the other by "l" for horizontal position. The maximum dimensions of the test panel are 210 x 297 mm.

News in cross hatch cutting

SledCutter 295 XVII & Multi-Cut Adapter for Corocutter 639

We introduce two advancements for precise and efficient cross hatch cutting:

The SledCutter 295 XVII elevates manual cross hatch cutting to a new level.

We introduce two advancements for precise and efficient cross hatch cutting:

The SledCutter 295 XVII elevates manual cross hatch cutting to a new level.

With adjustable cutting force and linear guidance, it enables the application of uniform, standardized cross-cut patterns on coated test panels – precise, fatigue-free, and safe.

Three different cutting tools (6x1 mm, 6x2 mm, or 6x3 mm) provide maximum flexibility for your testing needs.

The Multi-Cut Adapter enhances the functionality of our Corocutter 639, enabling precise, right-angled cross-cut patterns with adjustable cutting forces from 2 to 40 N. This guarantees consistently accurate cuts, revealing the substrate clearly.

Both devices contribute to making your testing processes more efficient and accurate

The Multi-Cut Adapter enhances the functionality of our Corocutter 639, enabling precise, right-angled cross-cut patterns with adjustable cutting forces from 2 to 40 N. This guarantees consistently accurate cuts, revealing the substrate clearly.

Both devices contribute to making your testing processes more efficient and accurate

Sample Preparation : CORROCUTER Smart 638

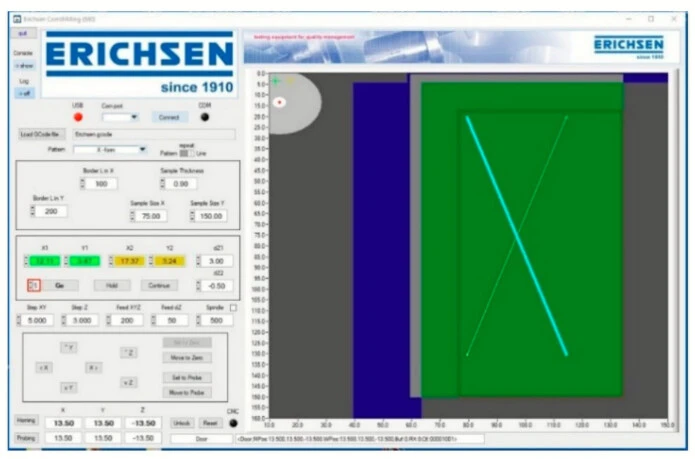

The automatic sample milling machine CORROCUTER Smart 638 for standard-conform defined cut "scribe" line application on coated test panels for corrosion testing.

Programmable process with excellent repeatability; incl. software for sample and cut positioning with preset programs as well as the possibility of setting own programs.

The automatic sample milling machine CORROCUTTER Smart 638 is a tabletop unit.

The electromotive drive ensures a constant feed motion of the cutting tool.

All functions are controlled by a comfortable, easy-to-use WINDOWS control software (operating system from WIN7).

All functions are controlled by a comfortable, easy-to-use WINDOWS control software (operating system from WIN7).

The software and a USB cable 2.0 are included in the scope of supply.

Technical Data

Dimensions (L x W x H) approx. 550 x 460 x 520 mm

Dimensions sample plate :

- max.210 x 300 mm (DIN A4)

- min. 75 x 102 mm

Mains connection : Table power supply (100 - 240) VAC, (47 - 63) Hz

Net weight approx. 13 kg

The right of technical modifications is reserved.

Ord.-No 101-03310131.

Automatic Milling Machine CORROCUTTER Smart 638, incl. drill millers

Heavy Duty Drive (HD)

Recommended for steel samples

Optional accessory for the CORROCUTTER Smart 638, the Heavy Duty Drive (HD) equipment.

It is a robust milling spindle with higher stiffness and a more powerful drive for creating corrosion scribes in very thick and high-strength coatings.

The scope of supply includes the HD milling head including motor (230 V), supply unit and necessary cable connections.

Corresponding HD drill miller (1.5 mm and 2 mm) can be ordered optionally.