K Control

Coatings & Industry > Physical properties > Film Applicators & Filmographs

K Control Coater

The K Control Coater is widely used for the application of paints, varnishes, adhesives, liquid printing inks and many other surface coatings to produce quick, accurate and repeatable samples. These may then be used for quality control and presentation purposes, R&D, computer colour matching data etc.

- Controlled speed and pressure ensures repeatable results.

- Coating by wire wound bars or gap applicators.

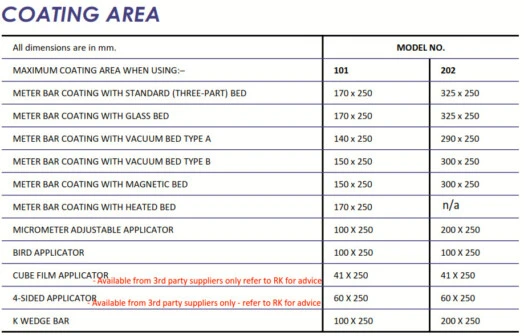

- Two models offer coating areas of up to 170 x 250mm or 325 x 250mm.

- Multiple coatings in one operation for comparison purposes.

- Standard coating speeds infinitely variable between 2 and 15m/m in.

Recommended for database and sampling use for computer colour matching, spectrophotometer readings, or other instruments.

METER BAR COATING

Meter bars provide the simplest method of applying accurate, repeatable surface coatings on to most substrates.

A meter bar is manufactured by winding precision drawn stainless steel wire on to a stainless steel rod, resulting in a pattern of identically shaped grooves.

These grooves then precisely control the wet film thickness.

Close wound bars produce a coating thickness from 4 to 120μm. Higher coating weights up to 500μm can be obtained using spirally wound bars.

A three-part melinex/foam/rubber coating bed is supplied as standard. Vacuum, magnetic, heated and glass beds are also available.