Scratch Tester 413

Coatings & Industry > Physical properties > Hardness

SCRATCH HARDNESS TESTER 413

(The top of the range instrument)

YOU BEST CHOICE when you need great accuracy.

The Mod. 413 is in comparison with Sclerometer much more precise than any Sclerometer ever could be .

Mod. 413 allows the scratch force in

steps of down to 0,01 N, whereas the situation of accuracy with a Sclerometer is with a tolerance of ± 10% of the spring’s end value .

Although

the springs are precision ones, they have an allowed tolerance : due to this, as an example when at the

Mod. 318’s scale 0,5 N is adjusted with the 3 N spring, in principle any real load value in the

range from 0,2 N up to 0,8 N would be possible.

So when you want accuracy, the 413 is your solution.

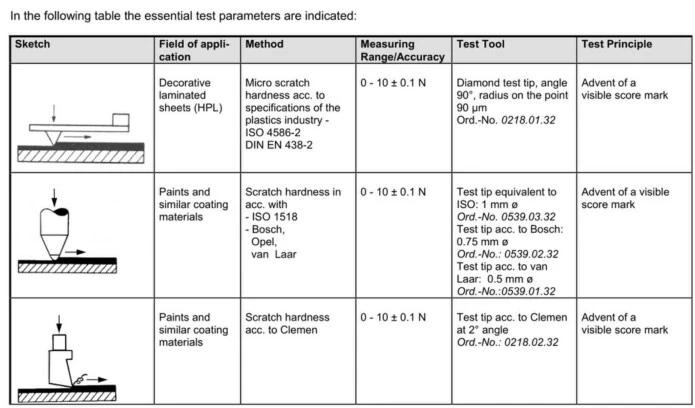

Most scratch hardness tests involve penetration into the material or coating to be tested until contact is made with the base material. For many versions of this type of test the sequence to do just that is all that is required.

However, very often it turns out to be very useful to find out what it takes to overcome first the resistance of the outer surface, before any more damage is done.

In addition to establishing what would cause the start of the full destruction of the coating resulting from damage to the outer surface the measurement also identifies first stage of harm to the appearance of the surface (for example in the coating on vehicles).

Damage to the top surface of a coating may also have a harmful effect on the functioning of the product – for example in the case of high-tech coatings on glass.

Because of the unique facility for adjustment the ERICHSEN SCRATCH HARDNESS TESTER 413 is ideally suited for identifying the small differences in scratch resistance.

The instrument offers the means for representing the surface quality numerically with good repeatability.

The scratch resistance of many products is now at such a high level that great differences in quality are not in general to be expected but even the small differences are of significant importance.

A higher level of sensitivity of the test method, which can differentiate between these, is therefore required.

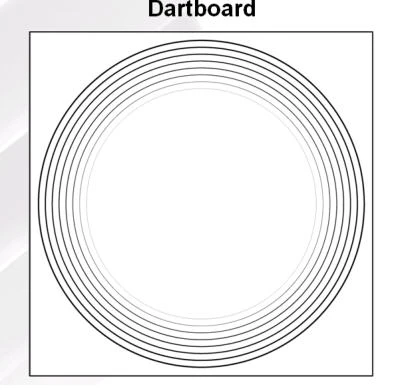

For the test using the SCRATCH HARDNESS TESTER 413 a series of parallel scratch marks is applied to the test surface.

The depth of the scratch marks is reduced from one line to the next by means of fine adjustment, up to the point where no scratch mark remains visible or is noticeable under an accepted definition.

Various types of scratch tools, ranging from sharp pointed to rounded and flat with sharp-edges are available so that the test can mimic the scratch effects to be allowed for under practical conditions to represent the product properties over as wide a range of conditions as possible.

The SCRATCH HARDNESS TEST ER 413 in this way covers a wide variety of scratch resistance as required for different materials: vehicle or general coatings or plastic surfaces of light switches and push buttons, mobile phone displays, handles, housing components, general displays, vehicle components, vehicle cockpit switches, plastic products in general use, small plastic components (with or without coating), glass, glass coatings, high tech glass coatings and coatings for spectacle lenses (made of glass or plastic) and many other examples.

In today’s world we are surrounded by a very wide range of materials, most being produced industrially.

The surfaces are intended to achieve specific surface qualities but often the manufacturers of many products for the home, car, train, tram, bus, office, etc often do not yet monitor the scratch resistance quality of these surfaces.

The application of the Erichsen Model 413 can in all such cases provide a basis for assurance of the surface quality of these products.

Test principle

All test methods applicable for this instrument are in principle based on the same test procedure:

The specimen is clamped on a turntable (number of revolutions of the standard version is 5 min -1 ).

The test tool is fixed on a load arm also equipped with an adjustable weight so that the pressure exerted onto the specimen material can be regulated.

NO OPERATOR INFLUENCE ON THE MEASURMENT.

The resistance of the specimen against this action is visually evaluated from the score mark (detailed information on the evaluation are given in the Operating Instructions).

SCRATCH HARDNESS TESTER 413 - Basic instrument

The scope of supply includes:

♦ load arm for fixing the test tool

♦ 2 weights for the load ranges 1 N and 10 N

♦ 1 counter weight with spirit level

♦ box level

♦ magnifying glass

♦ screw driver

♦ carrying case

♦ instructions manual

Ref. 101-0102.01.31