Dust Tape Kit

Coatings & Industry > Surface inspection

Dust Tape Test

Includes Dust Test Tape & Dust Test Comparator

Product Description

Dust Tape Test using the Dust Test Tape and Dust Test Comparator will allow you to assess the quantity and size of dust particles on blast-cleaned steel.

Dust particles on blast-cleaned steel surfaces may reduce the adhesion of applied coatings, and by absorbing moisture may promote the corrosion of the steel surface.

All items are supplied in an industrial Carrying Case with Dust Test Tape (60m), Dust Test Comparator and X10 Illuminated Magnifier.

Compliant to ISO 8502-3.

Dust Test Tape

Spare Dust Test Tape 25mm (1”). 60m Roll

Ref : 274-PS201.

Dust Test Tape When used with the Dust Test Comparator will allow you to assess the quantity and size of dust particles on blast-cleaned steel.

Dust particles on blast-cleaned steel surfaces may reduce the adhesion of applied coatings, and by absorbing moisture may promote the corrosion of the steel surface.

Compliant to ISO 8502-3.

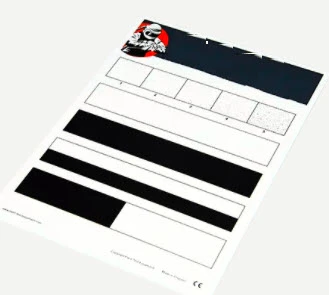

Dust Test Comparator

Ref : 274-PS202.

Dust Test Comparator when used with the Dust Test Tape will allow you to assess the quantity and size of dust particles on blast-cleaned steel.

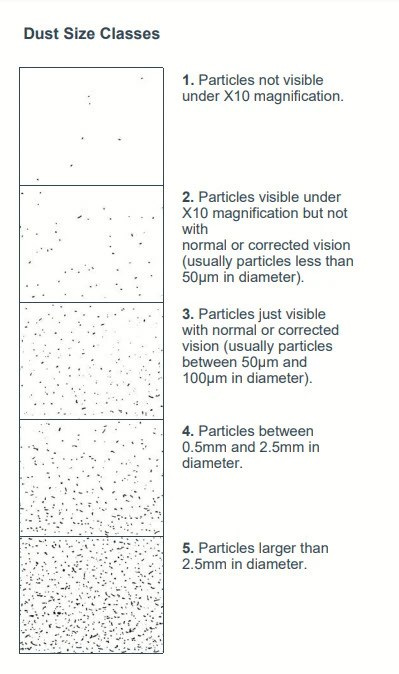

The Dust Test Comparator Chart shows 5 classifications of dust particles and 4 sections of contrasting backgrounds where the Dust Test Tape can be applied.

Compliant to ISO 8502-3.

Requirements: Dust quantity and dust size must not exceed class 1