Surface Tension Checkers

Graphic & Printing Industry > Ink properties > Surface tension

Introduction to surface treatment and dyne testing.

Surface Test Inks are primarily used to measure the surface energy of non-porous materials such as plastics, metal and glass surfaces in dynes/cm ( mN/m ) prior to printing, coating or adhesion.

Predominantly used in the Corona Treatment and Plasma Treatment processes of surface pre-treatment, promoting adhesion, to determine the cleanliness and the surface energy of substrates in the packaging sector, our Surface Test Inks can additionally be utilised in industries such as automotive engineering, aviation engineering, medical technology and electronics manufacturing.

The “surface energy” or wetting describes, the force formed by molecules of a substrate surface, “surface tension” being the liquid term. Both these terms are used to describe the molecule structure of the substrate surface.

To obtain a high adhesion “wetting” it is necessary to increase a substrates surface energy, this is achieved by surface treatment. Corona or Flame treatment give good results in

achieving this and greatly improve adhesion for printing inks, glues, and coatings of many materials.

In general it can be said that when printing, the surface energy of the substrate should be at least 10 dynes higher than the ink for good adhesion.

Measuring surface tension

Surface tension is an essential point for adhesion in printing, sticking process on plastic, metallic, and generally all non porous materials.

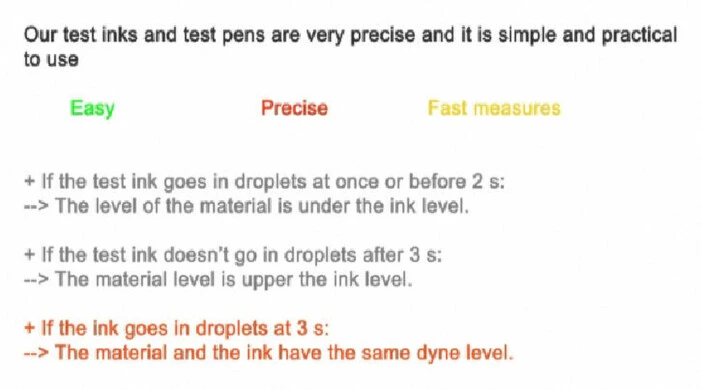

The control test pens and inks allow an accurate and quick determination of surface tension in dyne/cm (mN/m).

The control test pens and inks allow an accurate and quick determination of surface tension in dyne/cm (mN/m).

- Temperature correction : around – 1 dyne / + 10 ° C (regarding 20 °C ambiant)

- Avoid the contact with eyes, and skin (toxic, dangerous).

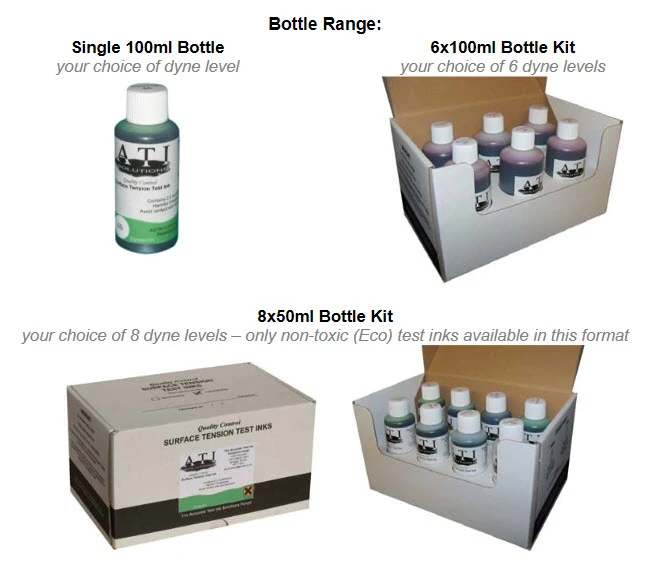

The Accurate Test Ink Solutions Range from 28 to 71 Dynes/cm (mN/m):

Non-toxic ASTM D-2578 compatible test inks.

Green Eco ink 26-58 dynes/cm (every dyne level eg:26,27,28,29,30,31) and

Red ink 59-71 dynes/cm (odd dyne levels only eg:59,61,63,65) : only non-toxic dyne inks available.

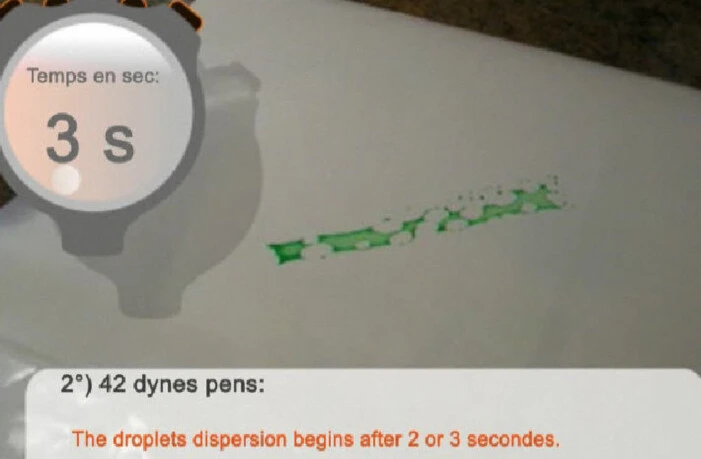

These non-toxic test inks are in their chemical structure obviously different in their reaction to any given substrate surface, here is brief guide to the reaction times to a plastic/film substrate surface when using Senze-Instruments Benelux products test ink.

Green – Eco Test Ink: 28 to 58 Dynes/cm (mN/m)

- Non-Toxic.

- ASTM D-2578 compatible test ink.

- Formulated to +/- 0.5 dynes/cm.

- Test observation time 3 seconds.

Red Test Ink: 59 to 71 Dynes/cm (mN/m)

- Non-Toxic.

- ASTM D-2578 compatible test ink.

- Formulated to +/- 1 dyne/cm.

- Test observation time 3 seconds.

Three common test procedures relating to our inks may be used:

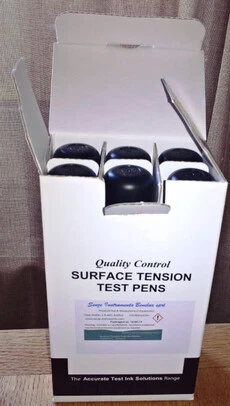

Disposable felt pen method: (Blue / Green / Red Test Pens)

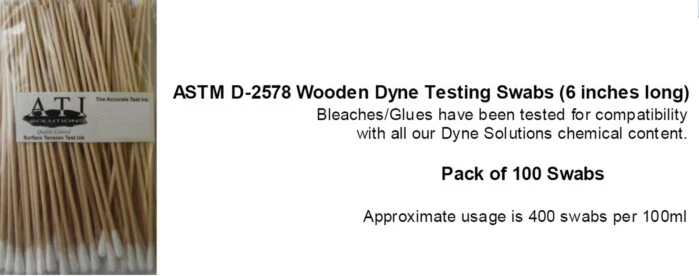

Cotton swab method: (Blue / Green / Red bottled ink)

Drawdown test method: (Blue / Green / Red bottled ink)

Note: we do not recommend the use of test ink bottles with integral brushes built into the cap. After the test procedure returning the brush to the bottle will undoubtedly result in contamination of the remaining test ink in the bottle.

This will lead to inaccurate test results over time.

Toxic ASTM D-2578 test inks,

Blue ink 38-58 dynes/cm (every dyne level eg: 38,39,40,41)

Inks are available in Pens (5 ml and 45 ml) and Bottles (50 ml and 100 ml)

Our Jumbo Test Pens use a 15mm nib that clearly displays test results, the nib can be changed if you suspect contamination from sources such high slip materials. Finally our Jumbo Test Pens use a valve system to prevent contamination of the dyne test ink.

Test pens are sold by box of 6 items (45 mL of ink in each pen).

The Test pens are designed with reservoir and released valves. The test pens are available prefilled or empty.

These systems allow to use virgin ink on demand.

5 ml Test pens are available in boxes of 10

38 dynes/cm Quick Check Pen 5ml (dries to leave a permanent display of the test result)

The 38 dyne quick check pen is not suitable for low solvent resistant surfaces like PVC

Also available:

40, 42 and 44 dynes/cm Quick Check Pens in boxes of 10

(do not dry to leave a permanent test result, these pens are used as our normal dyne products)

Here are some useful tips for our surface tension test pens:

- Avoid exposure to direct sunlight

- Keep containers tightly closed at all possible times

- The lifespan, if the pencils or flasks are frequently open, we recommend that you replace them regularly:

• Daily opening: 3 months storage.• Weekly opening: 6 months storage.• Monthly opening: 9 months storage.• Unopened: 12 months storage.

- To avoid inaccurate reading of the dynes level, do not store the pencils test ink at a temperature above 25 ° C or below 10 ° C.

- Take care not to pollute the tip of the pen, for example, by applications too frequent on materials containing a lot of slip agents.