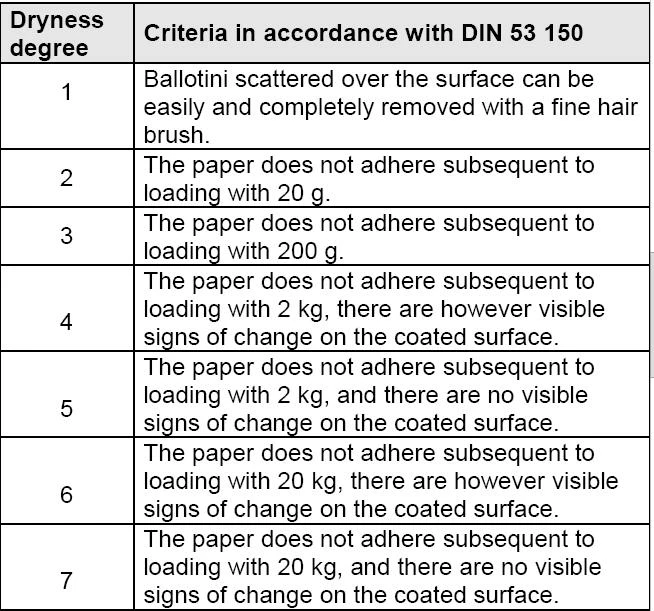

Drying time

Coatings & Industry > Physical properties > Drying Time

Drying Time Tester Model 415

For measuring the degree of dryness of coatings

DIN 53 150 - DIN EN ISO 1517

Purpose and Application

The Drying Time Tester, Model 415, is intended for the determination of the degree of dryness of coatings in accordance with DIN 53 150 (modified Bandow-Wolff method).

Technical Data

Dimensions: Width: approx. 150 mm

Depth: approx. 300 mm

Height: approx. 440 mm

Net weight: approx. 4.5 kg

Order Information

Ref 0093.01.31 Drying Time Tester, Model 415

Included in scope of delivery:

♦ Stand

♦ Individual weight for load of 20 g

♦ Individual weight for load of 200 g

♦ 2 soft rubber disks of 22 mm ∅

♦ 100 paper disks of 26 mm ∅

♦ Ballotini dispenser

♦ 50 g glass beads ("ballotini"), ∅ 125 - 250 μm, in compliance with DIN EN ISO 1517

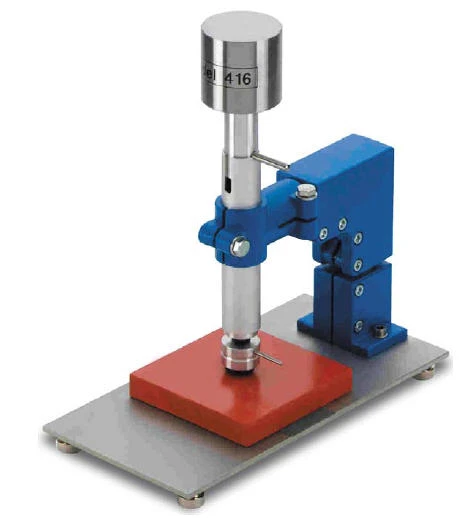

Through-DryTester Model 416

ISO 9117 - EN 29117

Purpose and Application

This instrument is designed for testing the through-dry state of paints, lacquers and similar coatings in accordance with the standards ISO 9117and EN 29117.

Principle of Test

A test plunger faced with nylon fabric and loaded with a defined weight is lowered onto the test surface for a limited period of time and

then turned through 90°.

The resulting effect on the coating is evaluated after lifting the test plunger.

Technical Data

Dimensions: Length: approx. 150 mm

Width: approx. 300 mm

Height: approx. 305 mm

Weight, nett: approx. 4.5 kg

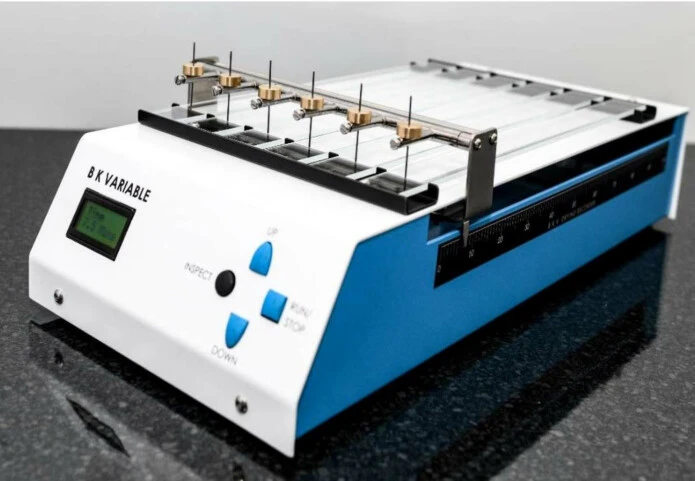

Drying Time Recorder Model 504-V

with variable speeds

Precise Recording of the drying Properties of Paints and Similar Coatings

Purpose and Application

The Drying Time Recorder, Model 504-V, automatically determines and registers the drying behaviour of paints and similar coatings.

Test Principle

A needle slides over the coating film at a defined speed. The track produced by the needle varies according to the degree of dryness.

The various drying stages are defined by calculating the time and track characteristics of the film under investigation.