Filmographs

Coatings & Industry > Physical properties > Film Applicators & Filmographs

Film Applicator BIRD 284

With 4 different gap heights of 30, 60, 90 and 120 µm (other gap heights on request).

The drawing edges of the standard version of this gap film applicator are ground to 4 different gap heights of 50, 100, 150 and 200 µm each so that it is possible to apply several corresponding theoretical film thicknesses using one instrument only.

The Film Applicator BIRD 284 is available with 6 different film widths between 50 and 250 mm.

It is corrosion resisting.

Film Applicator BAKER 286

The drawing edges of the standard version of this gap film applicator are ground to 4 different gap heights of 50, 100, 150 and 200 µm each so that it is possible to apply several corresponding theoretical film thicknesses using one instrument only.

The Film Applicator BIRD 284 is available with 6 different film widths between 50 and 250 mm.

It is corrosion resisting.

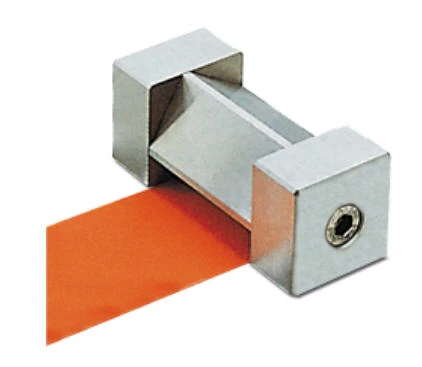

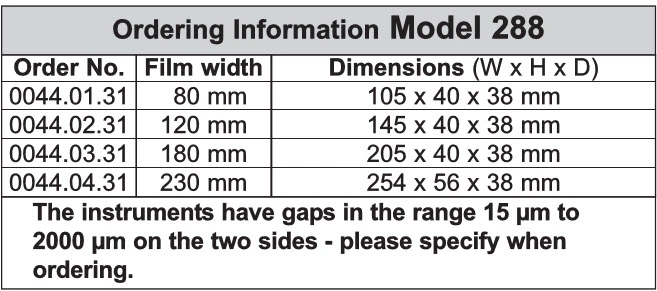

Film Applicator System Wasag, Model 288 (REFERENCE CLASS)

with different gap widths (13 mm, 40 mm, 60 mm, 90 mm)

with 4 different gap clearances (from 15 - 2000 microns available - please specify when ordering),

incl. case and Manufacturer's Test Certificate M

This filmograph is supplied with the blade at a fixed gap height, selected from a range between 15 and 2000 µm.

Model 288 with 2 working edges so that in this way several theoretical film thicknesses can be applied with a single instrument.

Model 288 is corrosion resisting.

Reference Class: All versions of Model 288 are supplied with a Manufacturer’s Certificate M in accordance with DIN 55350-18 that includes among others the following information:288

- Gap heights (comparison of setting/actual values),

- evenness and roughness of the working edge, product

- identification, test equipments used with calibration status,

- date, name of inspector.

For checking the film applicators maximum deviations of 5 µm/10 %/10 µm are fixed for gap heights in the measuring range below 50 µm/50 - 100 µm/over 100 µm.

The evenness/roughness should not exceed 3 µm/0.5µm (Ra).

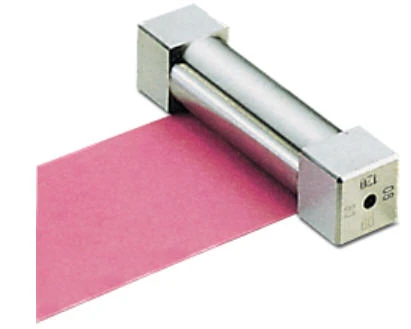

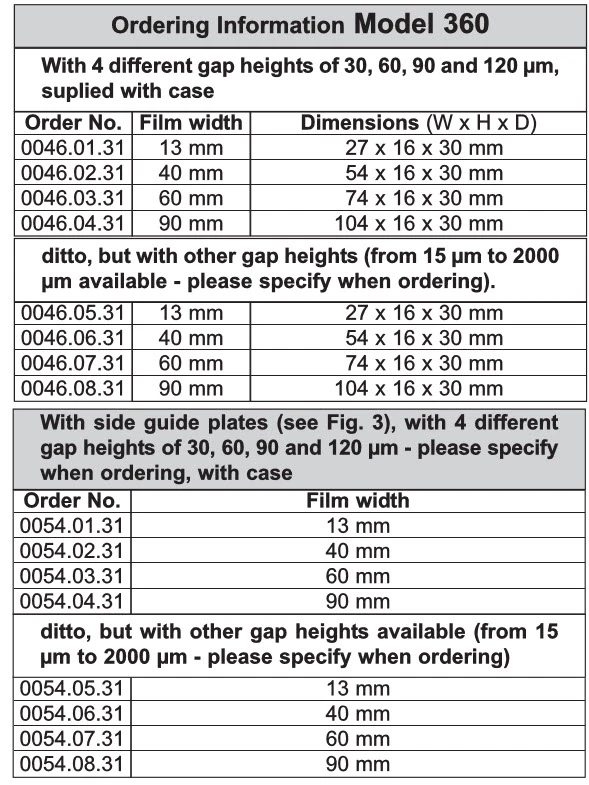

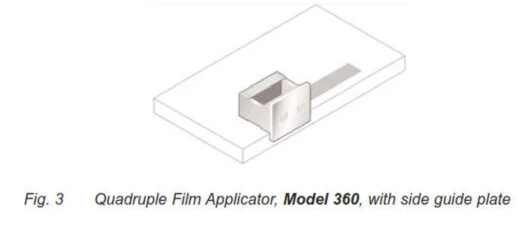

Model 360 fixed gap clearances

The Models 288 and 360 are doctor blades with fixed gap heights, selectable between 15 and 2000 μm.

The Model 288 is equipped with two applicator edges and the model 360 with four applicator edges, so that a corresponding number of theoretical layer thicknesses can be applied with one device.

Both blades are corrosion resistant.

All versions of the Models 288 and 360 are delivered with a manufacturer's test certificate M according to DIN 55 350-18, which contains the following information: Gap heights (nominal/actual comparison), flatness and roughness of the film applicator edge, roughness, test equipment used with calibration stand, product marking, date, name of tester.

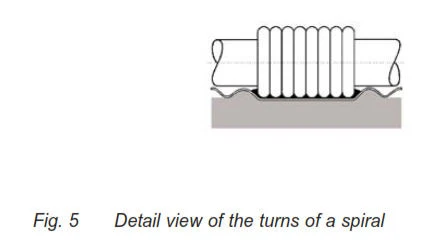

Spiral Film Applicator, Model 358

Cards, plastic foils, leather, textiles and other flexible substrates frequently have uneven surfaces or bulging shapes.

The use of a scraper type applicator can lead to uneven film thick-nesses.

The solution to this problem is the spiral applicator.

When the applicator is drawn across the substrate, the substrate is pressed down and held flat.

The grooves formed between the windings of the applicator have the effect of producing a wet film of defined thickness (Fig. 5).

The theoretical film thick-ness is controlled by the gaps between the windings of the spiral.

The roller with the spiral is held in a bracket with handle (Fig. 4).

The instrument is corrosion resisting.

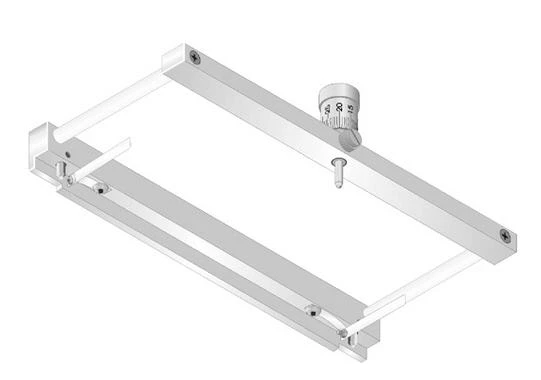

Film Applicator MULTICATOR 411

A frequent requirement is to produce a specimen panel with an accurately defined dry film thickness.

For the reasons gone into earlier it is necessary to conduct trials to find the corresponding theoretical wet film thickness.

It is of course possible to do this by using a series of applicator blades with different gap heights.

A simpler and more economical way is, however, to employ an applicator with adjustable gap height.

The infinitely adjustable film applicator Model 411 can be used to apply wet films with a theoretical film thickness of between 1 and 1000 µm.

The storage space is limited by spring strips and the desired gap height is set on a micrometer screw

The instrument is corrosion resisting.

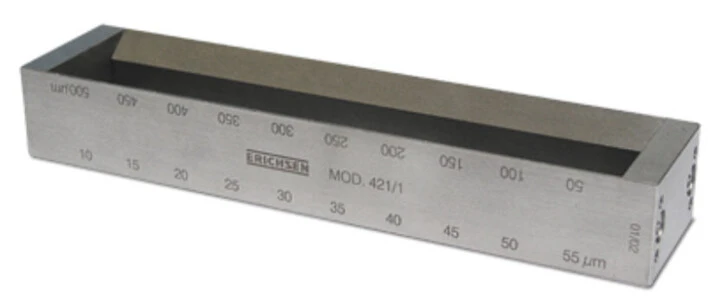

Staggered-Gap Film Applicator acc. to Krause, Model 421/I & 421/II

Purpose and Application

With Model 421 up to 10 parallel film strips of different thickness can be produced in a single application. This film applicator is therefore particularly suitable for investigations into properties that are dependent on film thickness such as

• Hiding Power• Adhesion• Colour strength• Effect formation• Hardening characteristics• Lacquer interference

When using the Model 421 in conjunction with the COASTER 509/MC-III it is possible to investigate hardening properties as a function of film thickness, immediately after application.

Furthermore, the Staggered-Gap Film Applicator 421 provides simple means for investigating the relationship between application parameters (height of gap, drawing speed) and the resulting film (wet and dry film thickness).