Galvano Test

Coatings & Industry > Physical properties > Thickness Dry Film

GalvanoTest

Ideally suited to measuring coating thickness in virtually any single or multi-layered coatings.

The GalvanoTest uses the coulometric method to measure galvanised coatings such as chrome, nickel, cadmium, copper, brass, silver, gold, tin or zinc both on metals and non-metals.

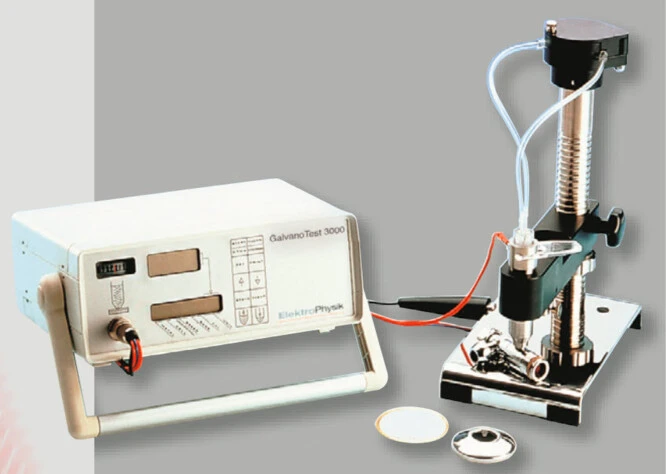

GalvanoTest: Coulometric coating thickness measurement gauge

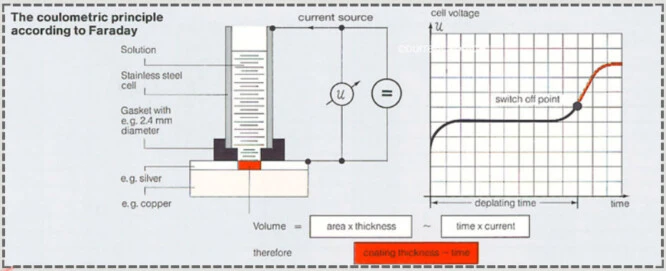

The anodic dissolution method, also known as the coulometric method, functions similarly to the electroplating process: an electrolyte separates individual metal coatings from the substrate with the help of an electric current.

By measuring the current and time, the GalvanoTest determines the thickness of the separated coating.

The GalvanoTest coating thickness measurement gauge is available in two variants:

- GalvanoTest 2000: the electrolyte is circulated by a pulsator nozzle.

- GalvanoTest 3000: large electrolyte volumes circulated by a circulation pump enable quick serial measurements. Suitable for use on very small parts and for the measurement of gold layers.

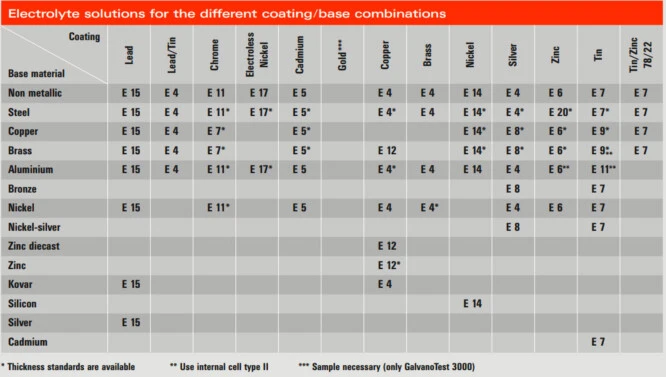

Coating/substrate combinations

- more than 70 coating/substrate combinations (standard version)

- coatings on flat and curved surfaces

- coatings on small components and wires

- 10 preset types of metal: Cr, Ni, Cu, brass, Zn, Ag, Sn, Pb, Cd, Au

- 8 further metal coatings for special applications

- measuring range: 0.05…75 μm

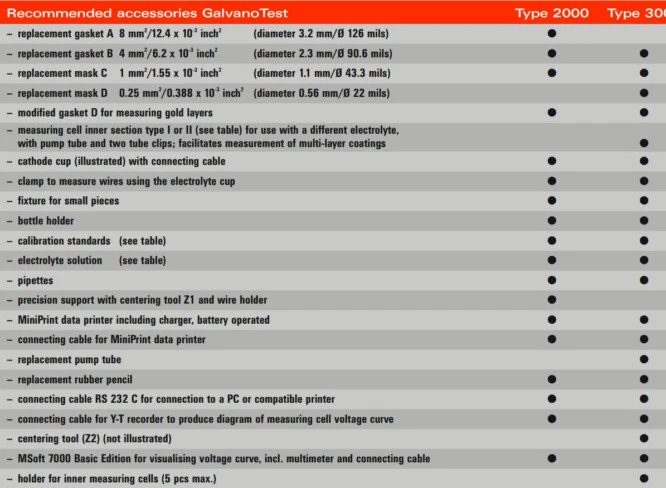

Measuring surface

- gasket 4 mm2/6.2 x 10-3 inch2

- mask 1 mm2/1.55 x 10-3 inch2

- mask 0.25 mm2/0.388 x 10-3 inch2 (deplated area nearly invisible)

- electrolyte cup 0.25 mm2 to approx. 16 mm2/(0.388–24.8) x 10-3 inch2 (optional)

- maximum of 8 deplating speeds in the range of approx. 0.3–40 μm (0.012–1.57) mils/min

- directly adjustable calibration factors; individual setting according tometal type and measuring surface

- calibration setting with the aid of thickness standards

- variable shut-down speed to suppress interference or for measuring alloy zonesbetween coating and substrate

Data storage with GalvanoTest

- number of memories for various metals: 18

- number of readings which can be stored and evaluated: 2000

- non-volatile memory retains all calibration settings, readings and statistical valuesafter the gauge has been switched off

Choosing GalvanoTest 2000 or 3000 ?

Two GalvanoTest models are available:

The GalvanoTest 2000 is the basic model and measures a variety of coating/base combinations without any accessories being required.

Designed for easy use, this model is mostly recommended for measuring multi-layer applications.

With the GalvanoTest 3000 additional measuring conveniences are provided. Its measuring stand with integrated electrolyte pump and easy to change measuring cell for automatic electrolyte removal and refilling enable electrolyte savings as one filling may be used for a large series of de-plating processes. Additional measuring cells may be purchased to house different electrolyte solutions for quick change over for multi-layer applications. Further advantages of the 3000 model: Even spots as small as 25 mm2 as well as gold layers can be measured easily without problems.

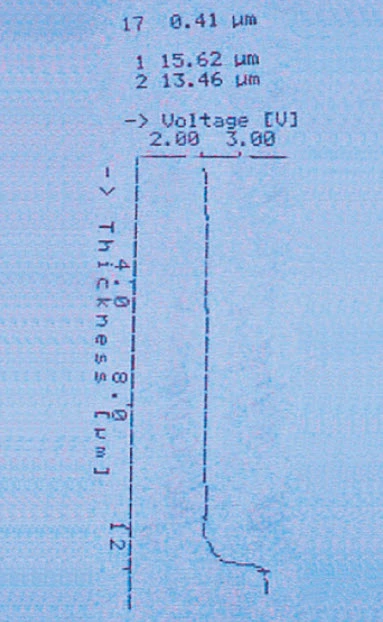

Measuring Cell Voltage Curve

The print-out of the characteristic

measuring cell voltage curve graphically represents the measuring pro cess with its typical voltage jump at

the end of measurement. The voltage jump terminates measurement

and thickness is automatically displayed in microns or mils.

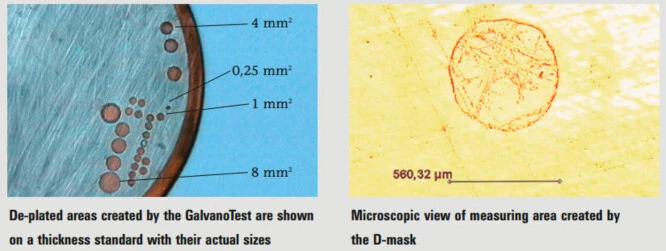

Size of De-Plating Area

The size of de-plating area can be precisely delimited using the supplied gaskets or masks.

The illustrations below represent the actual deplating area size along with a microscopic view of the measuring area delimited when using the D-mask (0,25 mm2).