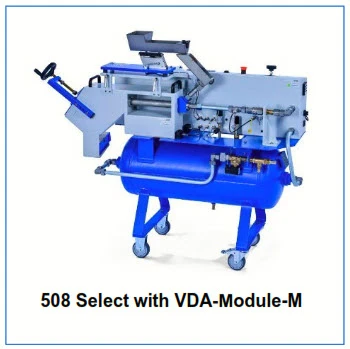

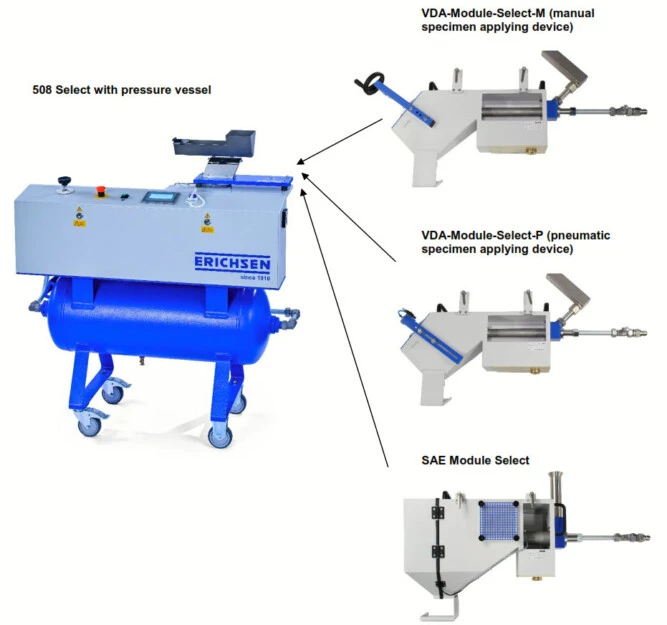

508 SELECT

Coatings & Industry > Mechanical properties > Flexibility and toughness > Stone Hammer Blow Tester

MULTI GRIT TESTER 508 Select

Multi-Blow Test Instruments for reproducible Test Results

Modular system with removeable bombardment attachment (VDA / SAE)

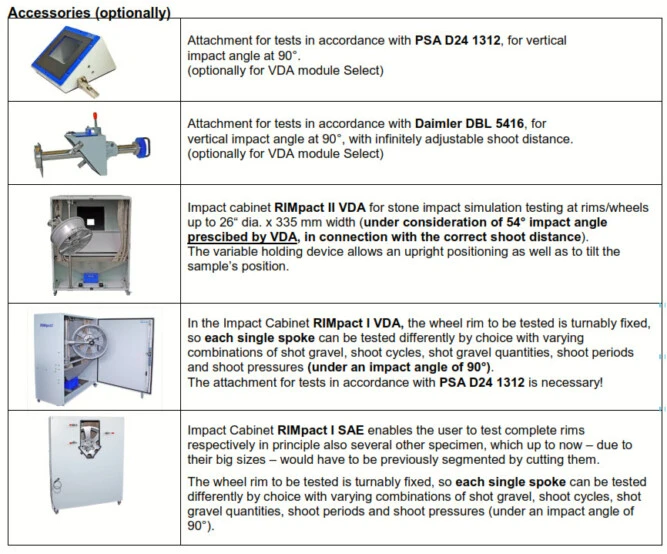

Optionally for VDA module: Attachment for tests in accordance with :

- PSA D24 1312

- Daimler DBL 5416

Technical Data

Dimensions (W x D x H) :

Basic instrument approx. 1150 x 550 x 1350 mm

Net weight (approx.) :

Basic instrument approx. 125 kg

- VDA-Module-Select-M approx. 19 kg

- VDA-Module-Select-P approx. 22 kg

- SAE-Module-Select approx. 34 kg

Compressed air connection:

(VDA) min. 6 bar / max. 10 bar, requires connecting hose with ID 13 mm

(SAE) min. 8 bar / max. 10 bar, requires connecting hose with ID 19 mm Volume flow: min. 3 m3/min

Filling pressure control:

- approx. 5 bar (VDA),

- 7.8 bar overpressure (SAE),

automatic switching depending on the module

Working pressure: (0 - 6) bar / adjustable

Time for feeding shot: adjustable

Display: Touch Panel

Power supply: 85-264 VAC / 47-63 Hz (control circuit volt. 24 V)

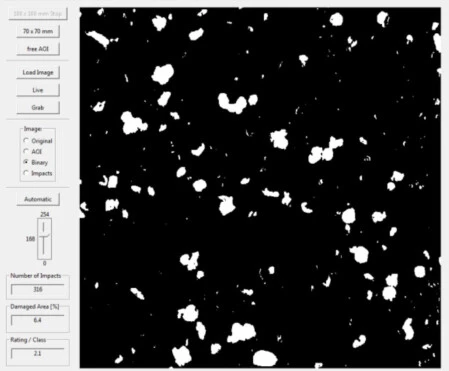

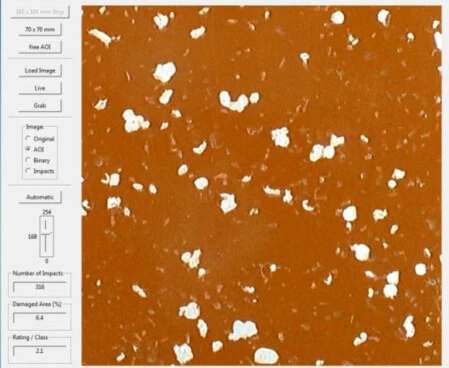

GRITSCAN.

For capture and analysis at impact images in accordance to VDA we recommend our new analysis system GRITSCAN.

Evaluation of results by camera system vs. manual result evaluation

• Any visual or manual evaluation, y ranking or classifying of the results is suffering

of the following:

– Visual evaluation & judgment trough the users‘ eyes include the “human error“– Individual impression by the user is time-limited in his mind & remembrance.– No digital documentation.

• An automatic evaluation by a digital vision system can provide the following advantages:

– Exclusion of the “human error“.– “Impression” is exchanged against measurement and the validity & access to the values is not time-limited.

– Objective, precise and repeatable results.– Digital communication