TABER® ABRASER 352 S - Typ 1700

Coatings & Industry > Mechanical properties > Abrasion & Washability

TABER® ABRASER 352 S (type 1700)

TABER® ABRASER 352 S - Typ 1700

The TABER® ABRASER 352 S (Platform), with its attractive and modern design, is a robust tabletop unit.

The precise control and drive elements are located in a sturdy aluminium housing.

Easy operation is via LCD touch screen, with functions such as abraser status, visual reference of completed test, cycle/time switching (completed or remaining), programmable pause interval, language selection and much more.

The TABER® ABRASER Model 352 S (Type 1700) has one specimen holder for performing abrasion tests.

“Taber Test” delivers reliable data in minutes.

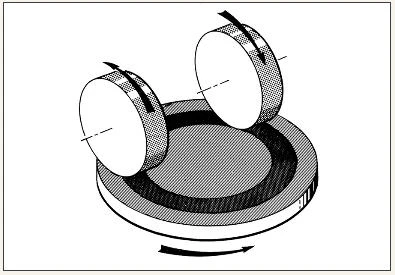

Used to evaluate a material’s resistance to wear, a flat

specimen is mounted to a turntable platform that rotates on a vertical axis. As the turntable rotates, contact

of the specimen against the sliding rotation of two abrading wheels cause wear while a vacuum system

removes loose wear debris during the test.

The resulting abrasion marks form a pattern of crossed arcs in

a circular band that cover an area approximately 30 cm2

.

TABER® ABRASER 352 D - Typ 1750

The TABER® ABRASER 352 D (Platform), with its attractive and modern design, is a robust tabletop unit.

The precise control and drive elements are located in a sturdy aluminium housing.

Easy operation is via LCD touch screen, with functions such as abraser status, visual reference of completed test, cycle/time switching (completed or remaining), programmable pause interval, language selection and much more.

The TABER® ABRASER Model 352 D (Type 1750) has two specimen holders for performing abrasion tests.

Evaluation

There are various techniques used to interpret results generated with the TABER Rotary Platform Abraser (Abrader). The method of evaluation that you select should reflect the type of material that is being tested. If you are following a specification - the method for interpreting test results will be listed.

The most common methods of evaluating results from the Taber Abraser (Abrader) include:

Cycles to a Specific End-Point - The number of cycles required to reach a predetermined end point, or the appearance or condition of the specimen after a fixed number of cycles. The evaluation criteria may include: loss in breaking strength, yarn breakage, loss in coating, change in gloss, color loss, or other changes in appearance. In these cases, the abraded sample is usually compared to a known standard of the material tested. When visually inspecting changes in specimen appearance, evaluations should be made using an agreed upon rating system such as a visual grading scale (e.g. five-step) or pass/fail criteria.

Weight (Mass) Loss - This technique measures how much material has been removed by abrasion, and is usually reported in milligrams.

L = A - B

where L = weight loss

A = weight (mass) of specimen before abrasion

B = weight (mass) of specimen after abrasion

When performing the weight loss method, loose particulate may adhere to specimens during testing. It is critical that you clean off the test specimens as best as possible prior to weighing.

Taber Wear Index - Indicates rate of wear, and is calculated by measuring the loss in weight (in milligrams) per thousand cycles of abrasion. The lower the wear index, the better the abrasion resistance.

I = [(A - B) * 1000] / C

where I = wear index

A = weight (mass) of specimen before abrasion

B = weight (mass) of specimen after abrasion

C = number of test cycles

Volume Loss - When comparing the wear resistance of materials that have different specific gravities, a correction for the specific gravity of each material should be applied to give a true measure of the comparative wear resistance. Calculate the wear index as shown above, and divide the result by the material's specific gravity. The use of this correction factor provides a wear index related to the loss in volume of the material to which it is applied. When comparing materials of different specific gravities, test parameters must be the same including wheel selection and load.

Wear Cycles Per Mil (0.001 inch) - Used to express abrasion cycles required to wear through a coating of a known thickness.

W = D / T

Where W = Wear Cycles Per Mil

D = number of cycles required to wear coating through to substrate

T = coating thickness, mils

Depth of Wear - To determine the depth of wear, use a thickness gauge or other appropriate device to measure the specimen thickness on four points along the path to be abraded, approximately 38 mm from the center hole and 90° apart. Calculate the average of the readings. After subjecting the specimen to abrasion, repeat the measurements and average the readings. Calculate the difference. Alternatively, the depth of the wear can be measured with an instrument such as an Optical Micrometer.

Residual Breaking Force (textile fabrics) - This technique measures the effective strength of the fabric, or force required to break a specific width of fabric. To determine the individual breaking force of the abraded specimen use the procedure described in the ASTM D5034 and D5035 Standard Test Method for Breaking Strength and Elongation of Textile Fabrics. [Note, you must change the referenced distance between clamps to 25mm and horizontally place the path of abrasion on the abraded specimen midway between the clamps.] Report the breaking load to the nearest 0.5kg.

Average Breaking Strength (textile fabrics) - Calculated by averaging the breaking strength of the abraded specimens and the unabraded specimens, as determined by the Residual Breaking Force.

Percentage Loss in Breaking Strength (textile fabrics) - To determine the breaking load of the original fabric and the abraded specimen, use the procedure noted above (ASTM D5034 and D5035). Calculate the percentage loss in breaking strength to the nearest 1% for each lengthwise and widthwise directions.

AR% = 100 * (X - Y) / X

where AR% = abrasion resistance, %

X = breaking force before abrasion, g (lb)

Y = breaking force after abrasion, g (lb)

A c c e s s o r i e s

Art.-No. Description

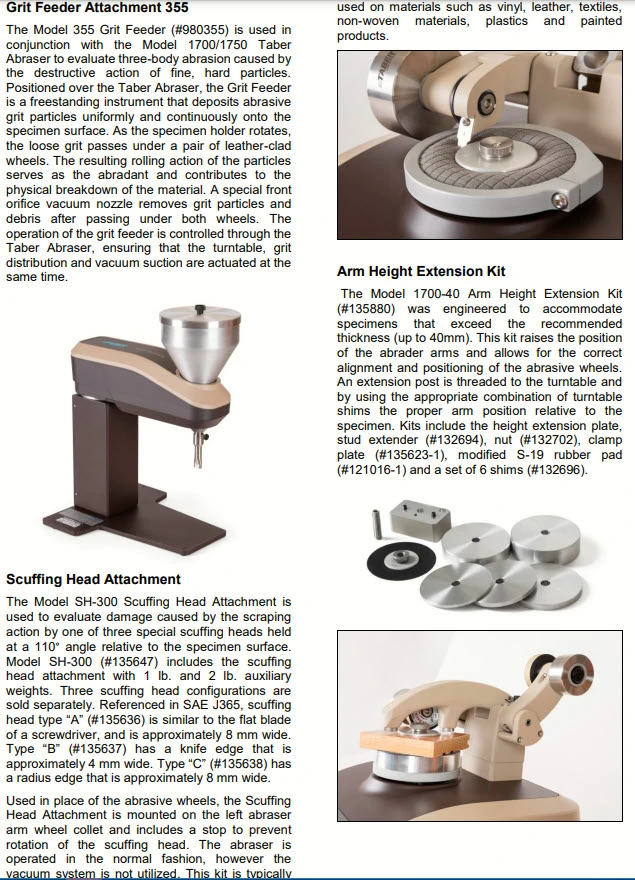

101-03524652 Quiet Cabinet, complete set (136134-230)

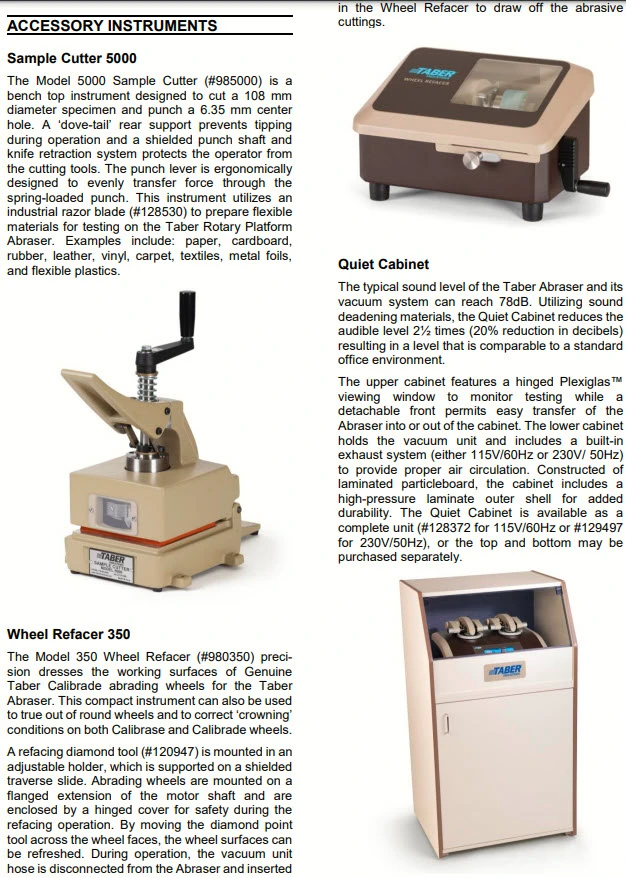

101-17000152 Wheel Refacer, Model 350

101-17000252 Single Point Diamond Tool (133-60) for Model 350

101-17000352 Multiple Point Diamond Tool (200-62) for Model 350

101-17003052 TABER® Grit Feeder 355 (980355)

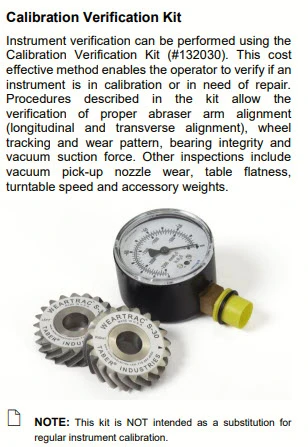

101-03525652 Rotary Abraser Calibration Verification Kit

101-03525752 Wheel tracking cards S-45 per 15 pcs.

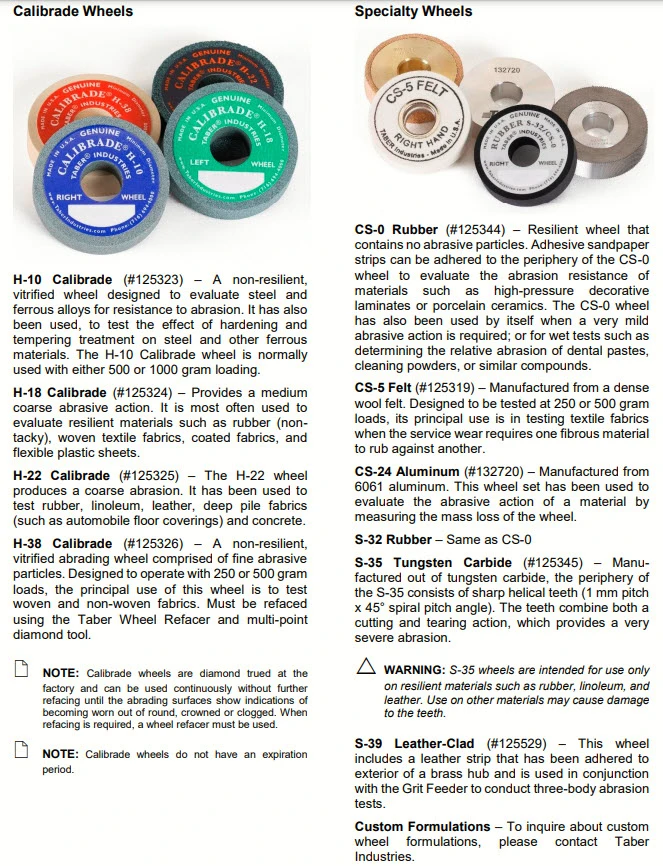

101-03526852 CALIBRASE wheels CS-8, purple, resilient, extra fine abrasion, per pair

101-03521752 CALIBRASE wheels CS-10F, brown, resilient, fine abrasion, per pair

101-03520753 CALIBRASE wheels CS-10, green, resilient, medium abrasion, per pair

101-03526052 CALIBRASE wheels CS-10W, white, resilient, medium abrasion, per pair

101-17000452 CALIBRASE wheels CS-10P, green, resilient, medium abrasion, per pair

101-03521852 CALIBRASE wheels CS-17, green, coarse abrasion, per pair

101-03526652 CALIBRASE wheels CS-T3 per pair red, resilient, fine abrasion (corresponds to old version of wheels CS-10F, type III)