High T° Oven

Laboratory Product > Heating

High Temperature Oven Stainless Steel Interior

The High Temperature Ovens model 21HT are ideal for all those applications where an accurate, reliable, and high- performance device is needed, and are used in research and biological, chemical, and pharmaceutical laboratories.

21HT High Temperature Ovens are essential in a wide range of tests and processes, such as thermostating, polymerization, heating, and drying process, in stability tests, accelerated ageing tests and sterilization treatments.

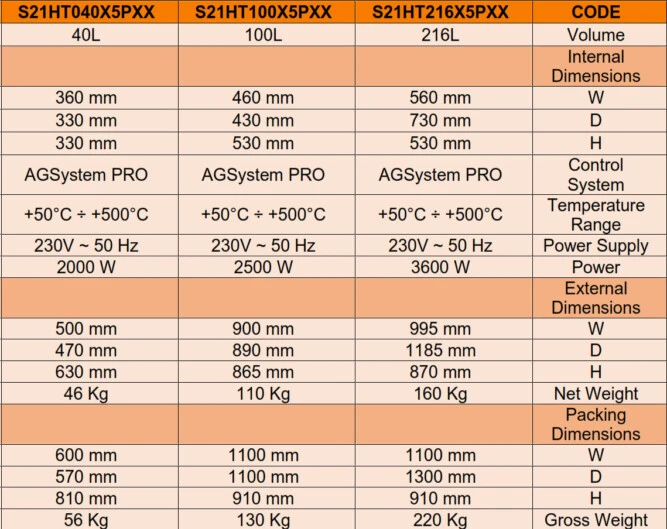

Temperature Range from +50°C to +500°C

Control System AGSystem PRO Microprocessor with Double Digital Display.

Intuitive Visualization of all functioning parameters.

Optimized Control Algorithm with PID Actions.

Autotuning Function.

High Temperature MgO Armored Probe.

“Zero Crossing” Solid State Relays.

Timer 99h 59m.

PROGRAM Function with Ramps, Soaks and Repetitions.

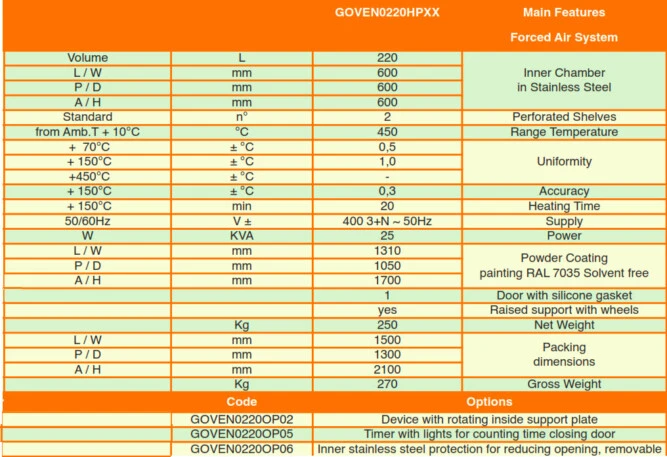

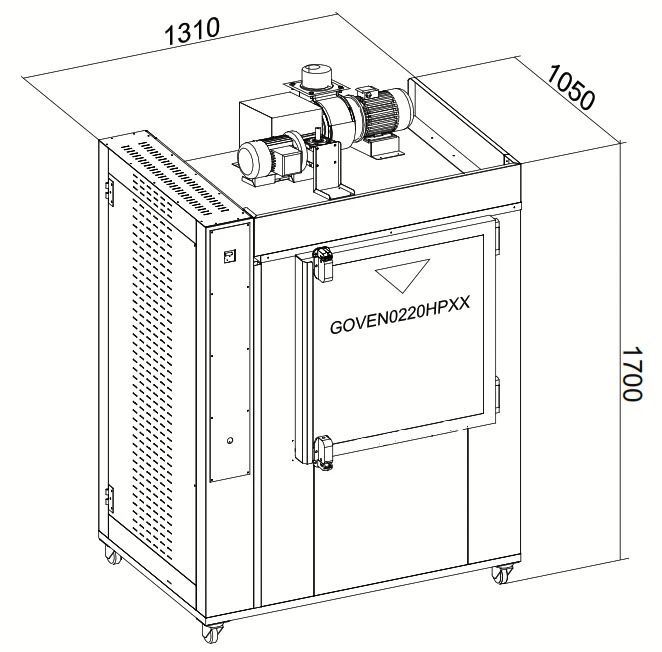

Goven 0220HP

Fast Precision Thermostatic Ovens

Thermostatic Ovens with Horizontal Forced Air for Fast Temperature Test, specific designed for test on paints,

And suitable for your applications:

- precise thermostating,

- heating, drying,

- polymerization,

- expansion,

- cooking,

- bonding,

- hardening,

- failure analysis,

- polyamide curing,

- accelerated aging,

- sterilizing,

- burn-in, inert

- atmosphere treatment,

- long-term storage.