Laboratory dissolvers - MIxers

Coatings & Industry > Physical properties > Mixer & Dissolver

DISPERMILL DISCOVERY® Laboratory Dissolver

The New Dispermill multifunctional Laboratory Dissolver of the Discovery line is a excellent user friendly machine for research and development of Coatings, Paints, Inks, Adhesives, Sealants, Cosmetics, Pigments, Pastes and Chemicals.

Dispersing, Mixing and Grinding of solids into liquids or liquids with liquids. Whether the liquid is Low, Middle or High Viscosity.

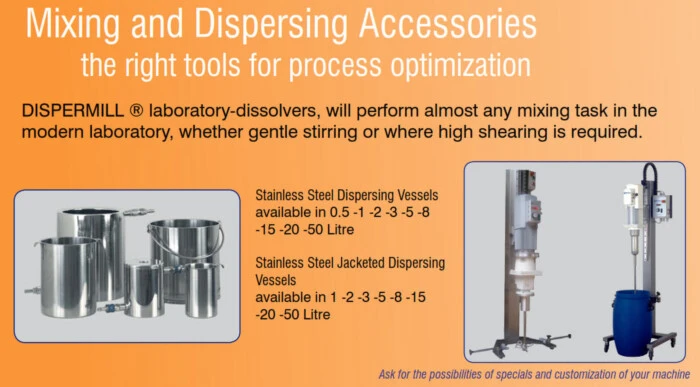

All process tasks can be done with one of our Dispermill machines at your choice. You can change every Dispermill machine with the following options : Vacuum/Scraper, Grinding /Basketmill, Mixer or Rotor Stator. Results can be scaled up for production

The powerful performance motor and PID electronics maintains its selected speed, independent of changes in viscosity and this guaranties an optimum dispersion process.

The modern stainless electronic stand is very comfortable in height adjustable.

Stainless steel food easy to clean.

New industrial colour operating panel with data storage option.

New Features

- Compact Full color LCD screen integrated on front.

- Multi Jog LED Interface knob, to give much faster control on the menu:

- Adjustable Timer with automatic stop

- Speed control starting from zero.

- Readout of Ampere.

- Readout of product temperature.

- New attractive design.

DISPERMILL DISCOVERY® Laboratory Dissolver : the family

The Nr. 1 allround dissolver

Dispermill Discovery® 100

from 100 ml - 10 liter

0,75 kW / 1,0 HP

0-12.000 RPM

1,3 Nm

230 Volt/50 Hz +/-10%

weight 55 KG

470x470x715/990mm. H

Dispermill Discovery® 100

Reference : 131-10-5100

Volume range : Dispermill vessels from 100 ml. up to 10 liter

Power : 0,75 kW / 1 HP

Supply : 230V +/- 10% 50/60Hz

Cooling : forced cooling, by low noise ventilator

Speed : from 0 till 12.000 RPM infinite adjustable

By integrated frequency inverter

Torque : 1,3 Nm

Thermal protection : motor and electronics has overloading protection by ptc temperature sensors

Plug and Play : The dissolver will be delivered including 1.5 meter power cord with plug

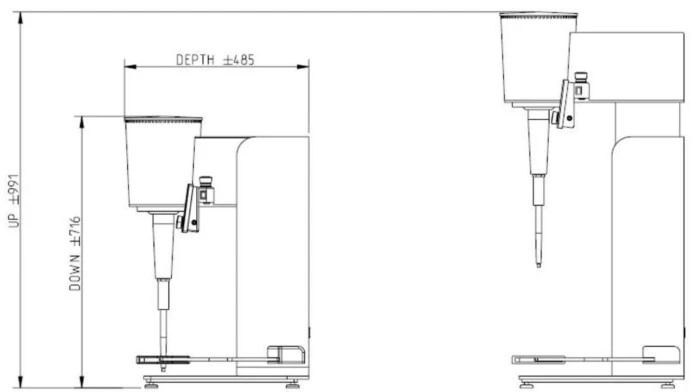

Height adjustment : Electronic adjustable by ergonomic lever.

Speed up and speed down 3 cm./sec.

Configurable:

• max. operating height• required lowest position for best vortex flow.

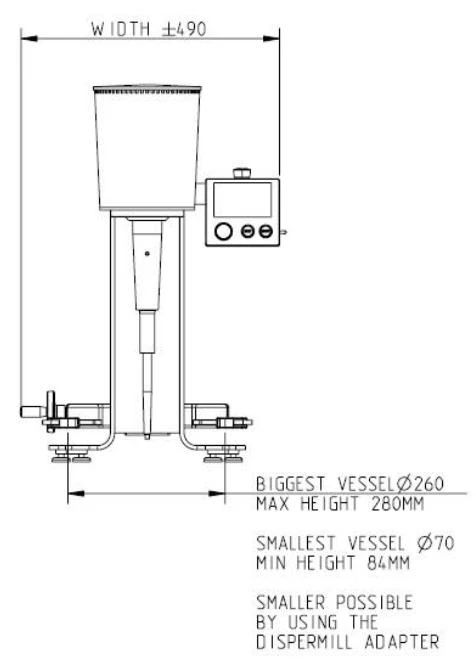

Stand Column : New compact design, electronic stand in solid stainless steel chemical resistant, flush and easy to clean.

Central clamping system : Two clamping arms with vessel detection and safety switch

Suitable for containers : from *100 ml till 10 litre. (*adaptor required)

Diameter container : from 70 mm till 260 mm.

Max height container : 280 mm.

Dissolver shaft : Dissolver shaft in stainless Steel, the dissolver bearing house is provided with double bearings.

Dispersing disc : in stainless steel, 70 mm. interchangeable

1345-12-1021 PT100 temperature sensor including adjustable vessel holder

134-12-1029 Removable telescopic shaft protector in stainless steel for Discovery 100

Laboratory Dissolvers and Pilot Dissolvers, Mixers and Mills.

Dispermill® Laboratory Dissolvers

- Compact Full color LCD screen integrated on front.

- Multi Jog LED Interface knob, to give much faster control on the menu:

- Adjustable Timer with automatic stop

- Speed control starting from zero.

- Readout of Ampere.

- Readout of product temperature.

- New attractive design.

- Ergonomic lifting handle.

Smallest high speed laboratory dissolver

Orange

- from 100 ml - 3 liter

- 0,30 kW / 0,4 HP

- 0 -10.000 RPM

- 0,5 Nm

- 230 Volt/50 Hz +/-10%

- weight 26 KG

- 500x360x710mm. H

Dispermill Pilot Dissolvers with floorstand

The Dispermill® Floormodel can produce outstanding results on most applications.

Low noise drive system with continuous adjustable speed.

PID electronics ensures constant speed even when viscosity changes.

Dispermill® Flame Proof Dissolvers

Explosion Proof Dissolvers with adjustable quick fit clamping devices, continues readout of Speed on clear digital blue display.

Complete Stainless steel stand, with very smooth action lifting device.

Model H-400 with floorstand

- from 15 liter till 150 liter

- 4,0 kW

- 0-4.000 RPM

- Dispersing Disc 175 mm.

- 400 Volt/50 Hz +/-10%

- Weight 200 KG

- 750x610x1759mm. H

Model X-Proof HX-400

- from 15 liter till 150 liter

- 4,0 kW

- 0-4.000 RPM

- Dispersing Disc 175 mm.

- 400 Volt/50 Hz +/-10%

- Weight 200 KG

- 750x610x1759mm. H

Dispermill® Dissolver from 60 liter - 500 liter

M-Series

- from 60 liter till 500 liter

- from 4 kW till 11 kW

- 250-2.500 RPM

- 400 Volt +/-10%

- weight 500 KG - 1000 KG

- 800 x1000 x 3350mm. H

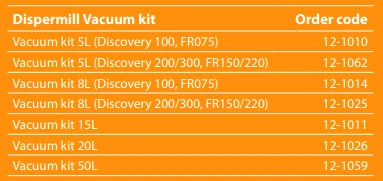

Dispermill® Vacuum Dissolvers

The solution for your vacuum process.

Several product require processing under vacuum.

All vacuumdissolvers will be supplied with special vacuumlid, vacuummeter two inspection windows and one porthole.

The Dispermill Vacuum dissolver is developed to enable a dispersion process in a closed system under vacuum.

The system prevents the formation of air bubbles in your viscous product during mixing or dissolving whether you are producing sealants, glues, gels or colourants.

The vacuum dissolver includes a lid that is made of high-quality aluminium, a vacuum gauge and vacuum valve.

The lid contains one porthole for the product inlet and two inspection windows to monitor the dispersion process.

If desired, the lid can be supplied with LED lighting.

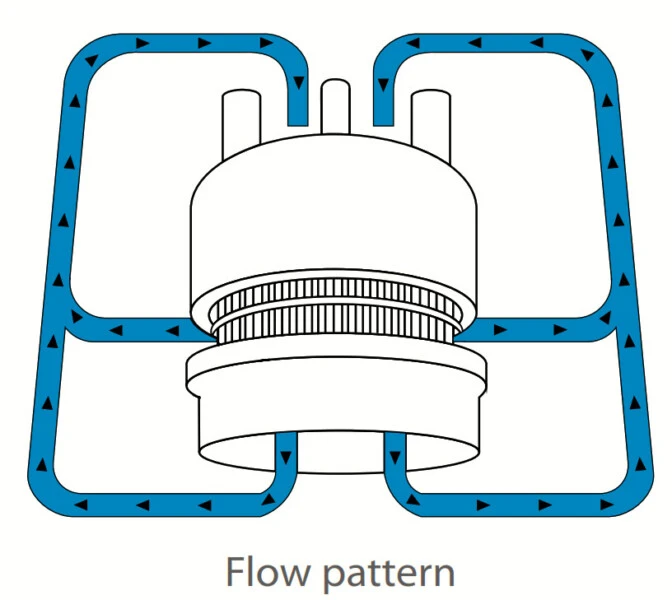

Dispermill® Basket Mill

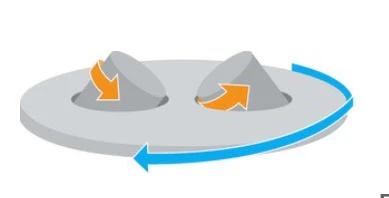

A Basket Mill combines mixing and milling achieving maximum particle size distribution, increasing production efficiency, and producing extraordinary quality!

The Patented system uses circulation milling technology by rapidly pumping the slurry through the media field.

Dispermill Immersion mill

With its innovative technology the Immersion mill combines mixing and milling achieving optimum particle size distribution, increasing production efficiency, and producing extraordinary quality. Immersion milling is a revolution processing technology that defies comparison. Its unique design and method of operation surpass all other systems, enabling the entire milling process to take place within a single milling chamber.

PATENDED TECHNOLOGY

Traditional milling is slow due to the low velocity of the feedstock passing through the shear zone.

To increase velocity, the intensity of the shear zone must be decreased.

Immersion milling works in an entirely different way.

Products are passed through an aggressive shear zone at very high velocity: as fast as 50 passes per hour.

This produces very narrow particle size distributions and decreases the bead to product ratio necessary for efficient milling.

High Speed Planetary Mixer

This new line of high shear centrifugal mixers has both dual speeds and vacuum versions.

The Dispermill® High speed Mixer performs the best homogenous mass of the best quality in a short time

- Removing Airbubbles from your product by centrifugal force and container rotation adjustment.

- Make it possible to perform uniform mixture between different raw materials and liquids with different specific gravity.

- Even materials with extreme high viscosities of thousands of mPa.s can be done very easily with one of the Dispermill® machines.

Examples of applied materials:

Epoxy resin, Silicone resin, Acrylic resin, Urethane resin, Polyimide, Wax, Grease, Lubricant, Oil, Various solvents, Silver powder, Gold powder, Copper powder, Carbon, Aluminum Pigment, Phosphor, Calcium carbonate, Tungsten, Titanium, Glass powder, Colorants.