Latest news

News - Service - Contact

New test available!

Is weld inspection one of your concerns?

New tool for inspecting welds between two sheets of DIFFERENT THICKNESSES.

Contact us for more info !

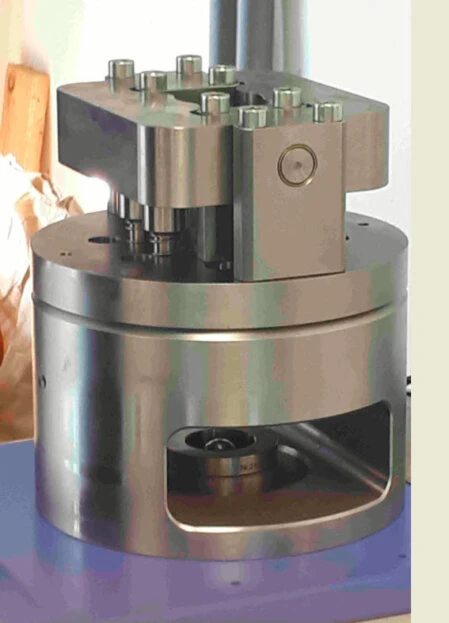

Ear Measuring Instrument, Model 126 Plus-Optic

for the axial, contactless measurement of deep-draw cups in the diameter range of approx. 25 up to 50 mm (other diameter on request) with a maximum height of approx. 100 mm.

The specimen is magnetically fixed to the turntable.

The measurement is carried out using an optical sensor, which enables contactless measurement. When the measurement starts,the optical sensor automatically moves to the measuring position.

The data transfer takes place via USB interface.

The measurement result can be output via supplied software on an external PC system (PC must be supplied by the user); incl. Manufacturer's Test Certificate M.

Display accuracy: 1/100 mm

Ref : 101-33970131

Film Applicator COATMASTER 510 Compact-G/V

Typical users are:

The lacquer and paint industry, especially for the research / development / quality control of many different products.

Generally universities / academies as well as institutes studying high sensitive facts within the scope of their research and development projects requiring an optimally controlled film application,

i.e. in the research of solar cells, fuel cells and accumulators as well as in the medical technology and research.

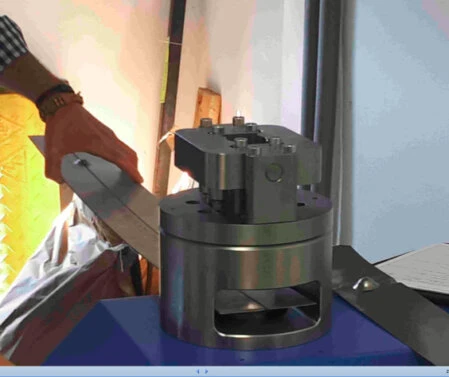

Heavy Duty Drive (HD) CORROCUTTER Smart 638

Recommended for steel samples

Optional accessory for the CORROCUTTER Smart 638, the Heavy Duty Drive (HD) equipment.

It is a robust milling spindle with higher stiffness and a more powerful drive for creating corrosion scribes in very thick and high-strength coatings.

The scope of supply includes the HD milling head including motor (230 V), supply unit and necessary cable connections.

Corresponding HD drill miller (1.5 mm and 2 mm) can be ordered optionally.

Our recommendations

- Vacuum up dust after each cut.

- Clearly define the load required to penetrate the coating for each test.

- Ensure that the back of the test piece is clean, free of paint, flat, and free of labels.

- Magnets can be attached to correct bending.

- For steel, the heavy-duty (HD) head is recommended.

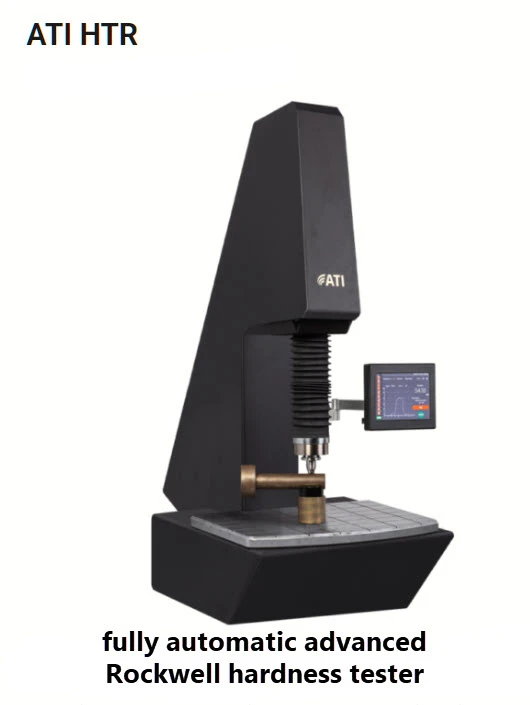

ATI HTR is a fully automatic advanced Rockwell hardness tester designed to accurately measure the hardness of ferrous, non-ferrous metals, and non-metal materials.

Test force closed-loop control system ensures precise automatic tracking and testing, eliminating any poten- tial errors caused by deformation of the frame or workpiece.

The measuring head offers automatic vertical movement, allowing for quick and secure clamping of workpieces without manual application of preliminary test force.

Motorized and Automatic Rockwell and Superficial Rockwell Hardness Tester, engineered to meet the rigorous standards set forth by ASTM E18, ISO 6508, and ISO 2039-2. This advanced testing instrument employs a high-precision load cell and Closed-Loop electronic control with a 1 KHz sampling rate, ensuring optimal accuracy and reliability.

The automatic start test cycle is initiated with a single input command, streamlining the testing process and enhancing efficiency. ATI MRS is designed to accurately measure the hardness of ferrous, non-ferrous metals, and non-metal materials. Engineered for high accuracy, this tester meets the needs of manufacturers and engineers who require precise hardness measurements in critical applications.

Automatic Rockwell and Superficial Rockwell Hardness Tester, engineered to meet the rigorous standards set forth by ASTM E18, ISO 6508, and ISO 2039-2. This advanced testing instrument employs a high precision load cell and Closed-Loop electronic control with a 1 KHz sampling rate, ensuring optimal accuracy and reliability.

To begin testing, users simply rotate the handwheel, raising the screw until the standard block makes contact with the indenter, confir- med by the system’s buzzer and “OK” status on the display. At this point, the initial test force is applied, and the motor automatically initiates the application of the main test force.

Once the dwelling time reaches zero, the system automatically releases the main test force, retaining the initial force for final measurement.

ATI RS is designed to accurately measure the hardness of ferrous, non-ferrous metals, and non-metal materials.

Engineered for high accuracy, this tester meets the needs of manufacturers and engineers who require precise hardness measurements in critical applications.

Automatic Rockwell hardness tester with built-in image viewing

ATI IN is represents the ideal solution, the indenter has been specifically designed to reach deep cavities.

This allows you to measure hardness on parts that cannot be measured with a traditional hardness tester. ATI IN is the solution for hardness tests on components such as rings and tubes (with a minimum internal test diameter of 25 mm) or near flanges or shoulders.

The new structure of the indenter allows a direct view of the test point.

A single START button to start the entire test cycle: when the indenter comes into contact with the surface to be tested, the hardness test phases will begin in automatic succession without interruptions.

Preload and load are managed electronically in “Closed-Loop” combined with an electronic load cell system.

Each step of the test cycle appears automatically on the touch screen display built into the body of the hardness tester.

The measurement software is intelligent and easy to use: select the hardness scale, the force value is automatically changed according to the preset test parameters

LV Rotating spring viscometer with 7’’ Touch screen

COMPATIBLES MEASURING SYSTEMS SPECIFICATIONS

- Spindle LV Spring,

- Spindle RV Spring,

- Spindle SV Spring,

- Spindle ULA Spring

COMPATIBLES TEMPERATURE CONTROLS* OPTIONS & ACCESSORIES

- EVA LR,

- EVA MS DIN,

- RT-1 PLUS.

*only with adaptation accessory RT1/EVA MS-DIN (Ref. 111-SP01KI

RV Rotating spring viscometer with 7’’ Touch screen

COMPATIBLES MEASURING SYSTEMS SPECIFICATIONS

- Spindle LV Spring,

- Spindle RV Spring,

- Spindle SV Spring,

- Spindle ULA Spring

COMPATIBLES TEMPERATURE CONTROLS* OPTIONS & ACCESSORIES

- EVA LR,

- EVA MS DIN,

- RT-1 PLUS.

- *only with adaptation accessory RT1/EVA MS-DIN (Ref. 111-SP01KI

Helipro Spring

The HELIPRO device makes it possible to measure viscosity of gels, pastes, creams and more generally products that do not flowing.

When a measuring mobile turns in this type of product, we can observe appearance of cavities around the rotating spindle which has effect of reducing measured viscosity values.

Through its movement vertical, HELIPRO system with its mobile T shape will prevent formation of cavities within product and will ensure reliable and consistent measurement.

This accessory is compatible with viscometers and rheometers from the LAMY RHEOLOGY range except FIRST PRODIG CP-1000, RM 100 CP1000/2000 PLUS, RM 200 CP-4000 PLUS, GT-300 PLUS, GT-300 PRODIG and DSR 500 CP-4000 PLUS.

Spring Thermosel Package

FEATURES AND BENEFITS

• Temperature range from Room T°C to +300°C.• Economic electric oven.• Compatible with bayonet coupling device.• Use of disposable aluminum cups.• Compatible with ASTM D4402 and D3236 standards.• Compatible with LV-SPRING and RVSPRING instruments.

Spring viscometer Small Volume Accessories

MS-ULA Spring

Water Jacket CT-LC-Spring

Small volume Kit Spring

MS-SV Spring

Measuring system with screw coupling

Still using tap water for your cooling needs?

Grant’s Ecocool Refrigerated Circulating Baths offer an efficient, sustainable alternative that helps you cut water waste and reduce lab costs without compromising performance.

Designed for precise temperature control and reliability, Ecocool keeps your processes running smoothly while eliminating the need for constant tap water flow.

From rotary evaporators to condensers, it’s the smarter, greener choice for modern labs.

Reliable cooling. Real savings. Better for the planet.

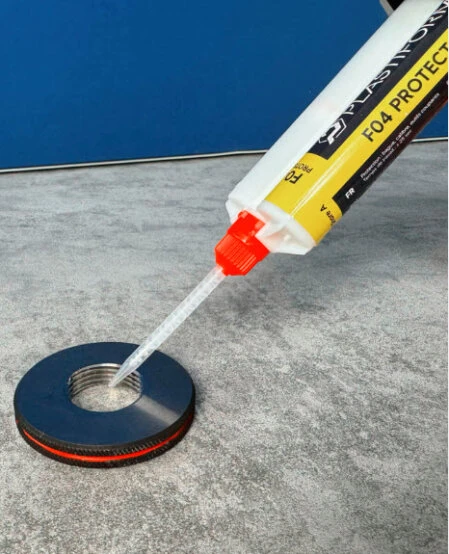

F04 PROTECT : Tools, Plug & Gauge RUST Protection

Key information

- Shape memory impression .

- Protects against moisture and corrosion.

- Incompatible with dimensional measurement.

- Absorbs shocks and protects the wrapped part.

This product is designed to protect fragile parts and components by enveloping them in a thick protective layer that effectively shields surfaces from impacts. It also provides excellent protection against moisture and corrosion.

It remains fluid for 20 seconds before it begins to harden, forming a highly flexible and durable material.

Once hardened, it reaches its final shape and stays firmly in place, fitting closely to the surface to provide perfect protection and sealing. This makes it easy to use for protecting a large number of parts at the same time.