Vickers

Metal Testing > Hardness Testers > Benchtop

LD 3000 AF

Automatic hardness tester for Rockwell, Brinell, Vickers and CHD test methods in compliance with ASTM and ISO hardness standards.

The LD 3000 AF is built for measuring the thickness of the superficial hardness and will determine (CHD) Case Hardness Depth from 0.12 mm to 2 mm, with no need to destroy the specimen or to separate material types before performing the test.

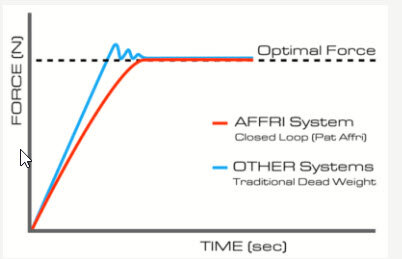

With just one measurement it reduces hardness testing time and costs compared to traditional polished cross section of Vickers and knoop methods. Load forces are applied through load cells and electronically controlled in Closed Loop (Pat. Affri).

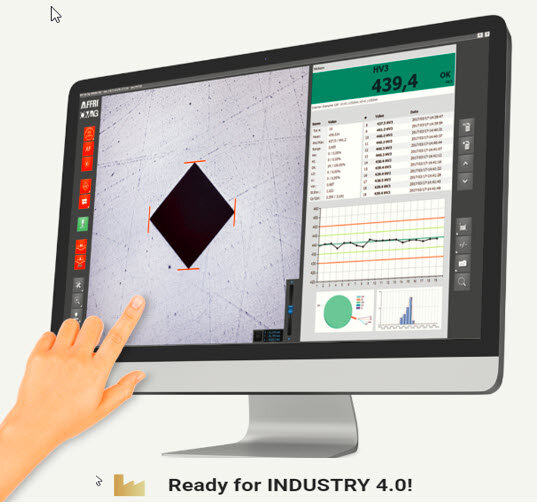

This hardness tester is entirely motorized and it is equipped with a wide touchscreen for ease in test planning and a clear view of results.

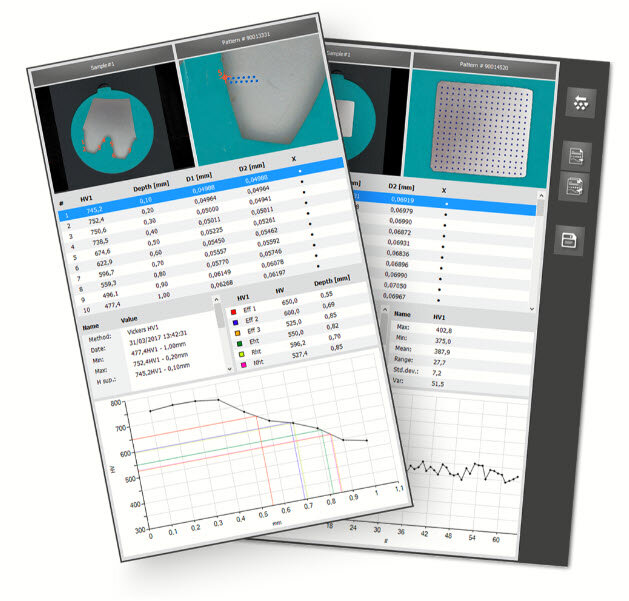

Statistics and CHD charts are automatically generated and can be stored with the test session in the large archive.

User friendly interface with conversion tables and round correction values for tests on covex cylindrical surfaces or various diameters.

For hardness case depth test with non-destructive method on all metals: Iron, steel, tempered steel, cast iron, brass, aluminum, copper and metal alloys.

Heat treatment, hardening, nitriding, cementation and hardfacing.

Test loads: from 10 to 3000 kgf (From 29,4 to 29403 N)

Hardness tester for Vickers and Knoop tests

Microhardness testing machine WIKI 90 CNC is a Vickers and Knoop hardness tester with test loads from 10gf to 62,5 kgf (at request from 1gf).

This hardness tester is suitable to test Micro Vickers, Macro Vickers, Knoop, and Brinell hardness test scales.

WIKI 90 CNC is conformed to all hardness standards including ASTM and ISO.

Test loads : from 10 gf to 62.5 Kgf (from 0.098 to 612.9 N)

Vickers ISO 6507 / ASTM E-384 / ASTM E-92

- HV0.001 – HV0.005 – HV0.01 – HV0.015 – HV0.02 – HV0.025 – HV0.05 – HV0.1 – HV0.2 –

- HV0.3 – HV0.5 – HV1 – HV2 – HV3 – HV5 – HV10 – HV20 – HV30 – HV50

Knoop ISO 4545 / ASTM E-384 / ASTM E-92

- HK0.01 – HK0.02 – HK0.025 – HK0.05 – HK0.1 – HK0.2 – HK0.3 – HK0.5 – HK1

Brinell ISO 6506 / ASTM E-10

- HBW 1/1 – HBW 1/1.25 – HBW 1/2.5 – HBW 1/5 – HBW 1/10 – HBW 1/30 – HBW 2.5/6.25 –

- HBW 2.5/7.8125 – HBW 2.5/15.625 – HBW 2.5/31.25 – HBW 2.5/62.5

Motorized and automatic, the test is not affected by operator influences and can easily be used by operators of every level

AUTO-COMPENSATION OF ALL DEFLECTIONS

When testing unstable samples or deflecting parts, the AFFRI System will follow the sample without losing contact thanks to its infinite stroke for indenter and clamping hood.

Load forces are applied through load cells and controlled in “Closed Loop” with a frequency of 1 kHz, assuring perfect linearity in every range.

Results are not affected by any structural deflection, misalignment, or vibration.

Accurate measurements on the first test, even in extreme conditions, eliminate the need for repeated tests.

Accurate measurements on the first test, even in extreme conditions, eliminate the need for repeated tests.

The R&R data is at the top of its class.